The Brushes on DC machine are always placed on _______ in order to achieve sparkles commutation?

Right Answer is:

MNA

SOLUTION

Armature reaction occurs in DC motors and is caused by the stator magnetic field being distorted, or altered, in reaction to the armature magnetic field. The armature reaction is actually a bending of the motor magnetic field so that the brushes are no longer aligned with the neutral magnetic plane of the motor.

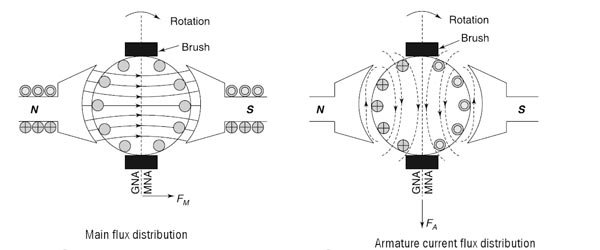

The figure depicts a two-pole generator whose field winding is excited and the direction of the magnetic flux is shown. Note that the flux distribution is uniform. Vector OFM represents the main field. It is observed that the MNA(Magnetic Neutral axis) which is always perpendicular to the field and GNA (Geometrical Neutral Axis) coincide with each other.

The second figure shows an armature connected to a load and armature current flowing through the armature conductors. This armature current produces its own magnetic field. The vector OFA represents the armature field.

The second figure shows an armature connected to a load and armature current flowing through the armature conductors. This armature current produces its own magnetic field. The vector OFA represents the armature field.

The second figure shows an armature connected to a load and armature current flowing through the armature conductors. This armature current produces its own magnetic field. The vector OFA represents the armature field.

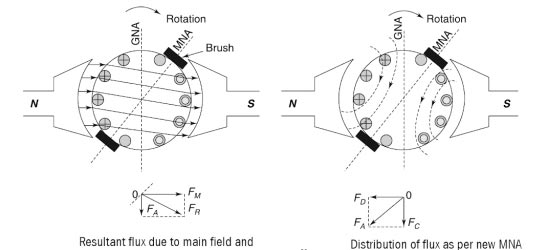

This armature flux interacts with the main flux and a resultant field is produced in the armature as shown in Fig. It can be seen from the figure that the resultant flux is not uniform. It is concentrated at the trailing tips of the pole and is rare (weak) at the leading pole tips. The resultant flux is shown by vector OFR which is the vector sum of OFM and OFA.

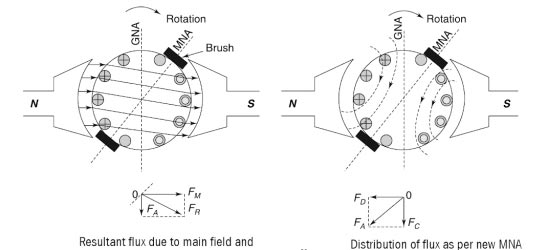

In general, the MNA shifts in the direction of the motion in a generator and in the opposite direction of the motion in a motor. So, in a generator, armature coils undergoing commutation are under the influence of the backward pole. This produces dynamically induced emf in the coils due to the cutting of the flux along the brush axis, which will try to maintain the current in the original direction. In the case of a motor, the coils are under the influence of forward poles. Therefore, there will also be dynamically induced emf in the coils. The extent of the MNA shift depends on the value of armature current and hence on the load of the machine.

We know that the commutator must short out the armature coils just at the moment when the voltage across them is zero. When the machine is loaded and the MNA shifts, the brushes short out the coils with some voltage in them. Therefore heavy sparking occurs as the brushes leave a segment. This is a very serious problem as it reduces the brush life and causes pitting of the commutator segments.

Moreover, the MNA shift can also lead to flashover in the commutator bars near the brushes. Air near the brushes in the machine is normally ionized when sparking at the brushes happens. Flashover occurs when the voltage of the adjacent commutator bars is large enough to sustain an arc. If a flashover occurs, the resulting arc can melt the surface of the commutator and cause severe pitting on the commutator surface.

Hence the brushes are shifted from the mechanical neutral plane in a direction opposite to the rotation to reduce sparking.