Cables and Connectors Multiple choice Questions and Answers

Ques.1. The bedding on a cable consists of

- Hessian cloth

- Jute

- Any of the above

- None of the above

Answer.3. Any of the above

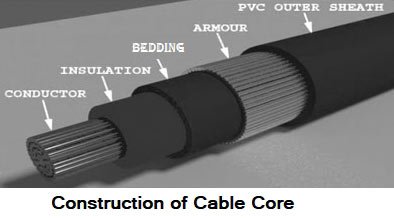

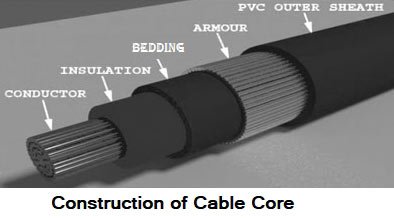

Bedding is provided for the protection of metallic sheath against corrosion and mechanical injury, a layer of “bedding” consisting of paper tape compounded with a fibrous material like jute or Hessian tape is used. This protects the metallic sheath from corrosion and mechanical injury due to armoring.

The compound used should be such that it does not react with the armoring material and lead sheath but at the same time it should be adhesive enough so that it sticks on, both to the lead sheath and armoring. Bedding is used in paper-insulated lead-covered cables but not in polyvinyl chloride (PVC) cables.

Ques.2. The insulating material for a cable should have

- Low cost

- High dielectric strength

- High mechanical strength

- All of the above

Answer.4. All of the above

Insulating material for a cable

The satisfactory operation of a cable depends to a great extent upon the characteristics of insulation used. Therefore, the proper choice of insulating material for cables is of considerable importance. In general, the insulating materials used in cables should have the following properties

- High insulation resistance to avoid leakage current.

- High dielectric strength to avoid electrical breakdown of the cable.

- High mechanical strength to withstand the mechanical handling of cables.

- Nonhygroscopic, that is, it should not absorb moisture from air or soil. The moisture tends to decrease the insulation resistance and hastens the breakdown of the cable. In case, the insulating material is hygroscopic, it must be enclosed in a waterproof covering like a lead sheath.

- Noninflammable.

- Low cost so as to make the underground system a viable proposition.

- Unaffected by acids and alkalies to avoid any chemical action.

Ques.3. The dielectric strength of rubber is around

- 15 kV/mm

- 30 kV/mm

- 200 kV/mm

Answer.3. 30kV/mm

Rubber is the most commonly used insulating material. Natural rubber is produced from the latex of the rubber tree. Synthetic rubber is produced from alcohol or oil products. Its relative permittivity is between 2 and 3 and dielectric strength is between 30 and 35 kV/mm. It absorbs moisture slightly and the maximum safe temperature as low as around 38°C.

Ques.4. In capacitance grading ______ dielectric is used.

- Homogeneous

- Porous

- Hygroscopic

- Composite

Answer.4. Composite

The process of achieving uniformity in the dielectric stress by using layers of different dielectrics 1s known as capacitance grading.

In capacitance grading, the homogeneous dielectric is replaced by a composite dielectric. The composite dielectric consists of various layers of different dielectrics in such a manner that the relative permittivity of any layer is inversely proportional to its distance from the center. Under such conditions, the value of potential gradient at any point in the dielectric is constant and is independent of its distance from the center.

In other words, the dielectric stress in the cable is the same everywhere and the grading is an ideal one. However, ideal grading requires the use of an infinite number of the dielectric which is an impossible task. In practice, two or three dielectrics are used in the decreasing order of permittivity. The dielectric of the highest permittivity being used near the core.

Ques.5. Underground cables are laid at sufficient depth

- T

- To avoid being unearthed easily due to removal of soil

- For all of the above reasons

Answer.1. T

In urban areas, underground cables form the bulk of connections for the electricity distribution system. 240 volts applies generally for single domestic supplies, and 440 volts for three-phase supplies, largely for industrial uses.

The depths at which cables are laid generally increase with the voltage with the aim being to provide a sufficient depth of cover over the cables so as to minimize potential contact by third parties, vehicles which can lead to serious hazards such as electric shock. At higher voltages cables are more likely to be installed in ducts and in all cases would be surrounded by sand to avoid the impact of bricks and stones damaging the cable when the trench is backfilled.

Ques.6. The material for armouring on cable is usually

- Steel tape

- Galvanized steel wire

- Any of the above

- None of the above

Answer.3. Any of the above

Armouring and covering: Armouring is provided over the bedding to protect the cable from mechanical injury while laying and handling it. It consists of one or two layers of galvanized steel wires or two layers of steel tape. The steel tapes are coated with preservative compounds and are helically wound on the cable insulation. Single-core cables in AC systems are not provided with armouring because eddy currents induced in the steel armour producing high loss. In these cables, plastic wrap is used for mechanical protection. Power cables are usually protected by bituminous compound wrapping (covering).

Ques.7. The cable used for high voltage application is

- Vulcanized Indian Rubber (VIR) cables

- Elastomer Insulated cable

- Polythene Insulated cable

- Gas-filled cable

Answer.4. Gas-filled cable

Gas pressure cables

Paper impregnated with petroleum jelly is normally used as the dielectric in gas-filled cables. The space between layers of paper insulation is filled with dry nitrogen gas with a pressure of 1400 kN/m2. This pressure is maintained constantly by pumps and by the lead sheath inside the cable. These cables are usually single-core cables and a small clearance is left to allow the gas to flow axially. In the case of three-core cables, clearance is not necessary because the filler spaces and strands allow the gas to flow.

High-pressure gas-filled cables. For this type of cable, the space for the gas is provided in the dielectric itself, which is filled up by inert gases like nitrogen at a pressure of about 6 atmospheres for extra high-tension voltage cables and 12 atmospheres for super-voltage cables. This facilitates the axial flow of gas, which also passes along the un-impregnated strand. This clearance is not essential in the case of multi-core cables because the filler spaces and strands provide a low resistance path for the flow of gas.

The advantages of gas-filled cables are:

(a) No external accessories are required.

(b) The cable can be used for the vertical run without any fear of leakage with suitable designs.

(c) With an increase in pressure, there is an improvement in the power factor of the cable dielectric.

(d) The extra super-voltage power cables are used for operating voltage beyond 132 kV.

Ques.8. In the cables, sheaths are used to

- Prevent the moisture from entering the cable

- Provide enough strength

- Provide proper insulation

- None of the above

Answer.1. Prevent the moisture from entering the cable

Metallic sheath: A metallic sheath is provided over the insulation to protect the insulation material from moisture, gases, and any other harmful liquids in the soil. It also protects the insulation from mechanical damage. The metallic sheath is usually made of lead or lead alloy. Nowadays, aluminum is also being used as a metallic sheath because of its greater mechanical strength, low weight, and cost as compared to lead sheath.

Ques.9. In a cable immediately above metallic sheath, ________ is provided.

- Earthing connection

- Bedding

- Armouring

- None of the above

Answer.2. Bedding

A layer of bedding is provided over the metallic sheath to protect it from corrosion and mechanical injuries due to armoring. Generally, bedding consists of paper tape which is compounded with fibrous materials such as jute or hessian tape.

Ques.10. Electric strength in a cable is more on

- Layer on the conductor

- Outside of the conductor

- The outer side of the armoring

- None of these

Answer.1. Layer on the conductor

The electric strength of insulation material is the ability to withstand an applied voltage without a breakdown. The voltage between the conductors at which the surrounding air is ionized is called the breakdown voltage or disruptive voltage. Break down voltage depends on atmospheric conditions and also surface conditions of the conductor. Electric strength in a cable is more on Layer on the conductor.

or

Electric strength is the maximum voltage that an insulating material can take, after which it loses its insulating properties. The higher the electric strength, the more useful is the material as an insulator. Hence the cable must be designed so that the electric field strength, or maximum electric stress, at the surface of the conductor, does not exceed that required to break down the insulation.

When the potential is applied to the conductors, a potential gradient is developed in the air. This potential gradient is maximum around the surface of the conductors. Due to the potential gradient, the free electrons will start moving with a certain velocity which depends on the field strength. The greater is the applied voltage, the higher is the potential gradient and the velocity acquired by the free electrons.

If the voltage is higher than the electric strength, an electric breakdown occurs. No matter which mechanism initiates the breakdown, the result is a sudden discharge of the voltage through the insulation. In cable insulation, such an event inevitably leads to a complete failure and an outage of the power line. The cable insulation must be designed such that it can withstand all expected voltages during the lifetime of the cable.

The electrical stress at the surface of a conductor is given by

${E_r} = \dfrac{{{V_{LN}}}}{{r\ln \left( {\dfrac{R}{r}} \right)}}$

VLN = The voltage between the inner cylinder (the conductor) and the outer cylinder (the Earth surface)

r = radius of the conductor

R = height of the conductor above the ground

When we want a low electric field strength at the conductor surface, we have to choose for thick conductors. By increasing the diameter of the conductor, the distance between the equipotential lines increases, and the electric field strength at the surface of the conductor, decreases. However, thick conductors are heavy and, besides the fact that more material is needed to manufacture them, they require more rigid tower structures which makes this solution an expensive one. A much better solution is to divide the conductor into bundles. Instead of one conductor per phase, multiple conductors are used per phase.