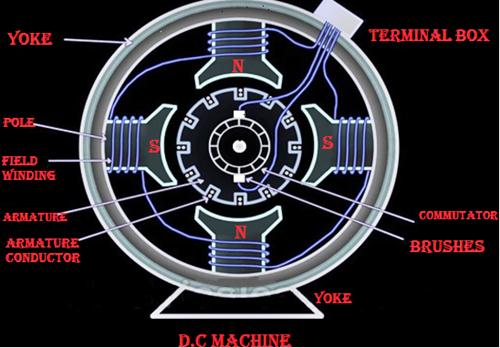

The principle of single loop DC generator has been described for the basic understanding of DC generator working. Now we will discuss the construction and working of actual generator.

The construction of DC generator and DC motor is same therefore instead of DC generator let say DC machine which is more appropriate and cover all aspect of DC motor and DC generator construction.

Direct current machine

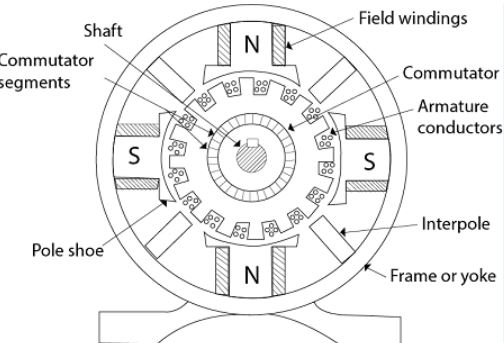

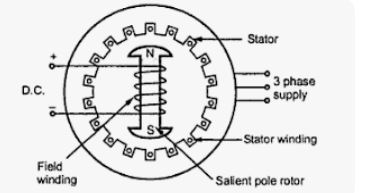

A D.C machine consist of two main part:

- Stationary part

- Rotating part

Stationary part:

- As the name signifies “stator” is the part which doesn’t move or remain fix in its position.

- The stationary part of the DC machine consists of main poles.

- The function of the main pole in DC machines is to provide a low reluctance path for the magnetic flux.

- A low reluctance path provides the stronger magnetic field.

- Other stationary parts of DC machine are frame/ yoke, field winding, pole shoe, etc.

- So it is clear that the function of stationary part is to provide a magnetic flux.

Rotating part:

- The rotating part of DC machine constituted of an armature core, armature windings, and a commutator.

- It is also called as an armature of DC machine.

- For generator mechacnical energy is converted into electrical energy.

- For motor electrical energy is converted into mechanical energy.

Let’s discuss the various part of DC machine in detail.

Frame/yoke

- The outer frame of a dc machine is called as the yoke.

- The York serve two main purposes:

⇒It provides mechanical strength to the whole assembly such as poles and acts as protecting cover for the whole machine.

⇒ It carries the magnetic flux produced by the field winding. - The yoke can be constructed using cast iron or cast steel.

- Cast iron is used for the smaller machine where cheapness is the main consideration.

- Cast steel or rolled steel is used for large D.C machine.

- The main disadvantage of using cast iron is that the cross-section of cast iron frame is twice that of the cast steel frame. Therefore DC machine becomes heavier in the case of cast iron.

- The advantage of the Fabricated yoke is that the mechanical and magnetic properties of the are consistent.

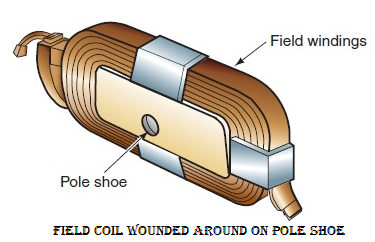

Field coil

- A field coil is an electromagnet used to generate a magnetic field in an electromagnetic machine, such as motor and generator.

- The field coil is also called as pole coil.

- The field coil is consist of wounded copper wire or strip which carries the current to produce the desired flux.

- Field Windings are wound all the poles with the particular current direction, and these windings are always connected in series.

- This field winding produces alternate North-South pole. Since the Magnetic line of force flow from North pole to the South pole.

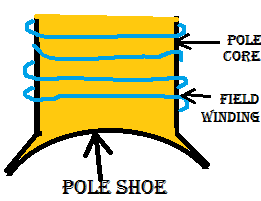

Pole Core

- The Function of pole core is to carry the field winding.

- The pole core serves two primary purposes:

- To support the field winding: Pole Core provides this area to wound the field winding

- To spread out the flux in air gap: Pole core direct the magnetic flux through the air gap, armature, and to the next pole.

So direction of flux is YOKE ⇒ POLE ⇒ ARMATURE ⇒ NEXT POLE ⇒ YOKE

- Pole core is either be made up of the solid piece of cast iron or cast steel or by the thin sheet of annealed steel lamination.

- The thickness of lamination varies from 1 mm to 0.25 mm.

Pole shoe

- Pole shoe is that part of the pole which will cover maximum armature conductors in its peripheral to cut the flux so that EMF induced will be more.

- Pole shoe is laminated and is fastened to the pole face using counter sunk screws.

Armature core

- The armature is the rotating part of DC machine.

- Iron is used to build the armature core because of its excellent magnetic properties.

- Eddy current in armature core is reduced by using lamination. So to reduce lamination core is made up of thin lamination.

- Armature slots carry the armature conductor. Armature conductor or Armature winding is just like the field winding made up of copper.

- Air duct in an armature core is provided for cooling purpose.

- It should be noted that the EMF in the armature is alternating in nature in DC generator.

Armature winding

- An armature is that part of the DC machine where EMF is induced.

- Armature coils are wound on the armature core and placed inside the armature slots.

Two methods can be used to wound armature coil:

- Lap winding

- Wave Winding

- From this armature winding, we can take current or a voltage out of the DC machine.

- Terminal box has two wire for input and two wires for outputs show in DC machine figure.

- The output wire is coming from the armature conductor, therefore from this armature winding, we can take current or a voltage out of the DC machine.

Commutator

- The commutator is a mechanical rectifier, so the commutator collects induced EMF or current developed in the armature.

- The commutator converts the alternating current generated in armature into the unidirectional current.

- The commutator is made up of Copper segments, and each segment is insulated from each other by the thin layer of mica.

- The number of commutator segments must be equal to the number of coils in the armature. That is, each commutator segment is in contact with two coil sides at all times.One coil side feeds the current to the segment, and the other side draws current from it.

- Hence, the number of commutator segments is equal to twice the number of coil sides, which is equal to the number of coils.

- Each commutator segment is connected to the armature conductor by using copper lugs.

Brushes

- We know that commutator is connected to the armature so as the armature is rotating (to cut the flux in order to induce the EMF ) obviously commutator will also rotate with the armature.

- So in order to collect the current, we should have something which is stationarily and can be fit into the commutator, and that is brushes.

- The number of brushes depends on how much current we need to tap from the commutator.

- Brushes are made up material like carbon, copper, and graphite.

- Copper brushes are used for the machine designed for large current at low voltage.

- Graphite and Carbon Graphite are self-lubricated therefore widely used.

Armature shaft bearing

- The ball bearing is used with the small machine.

- For larger machine roller bearing are used with the driving end, and ball bearing is used with the non-driving (commutator) end.