The deciding factor in the selection of a d.c. motor for a particular application is its _______ characteristic.

Right Answer is:

Speed-Torque

SOLUTION

Whenever the application of any machine is considered, its operating characteristics along with its economic and technical viability as compared to its competitors are the essential criteria. For a dc machine, of course, the main attraction lies in its flexibility, versatility, and ease of control. This explains why in spite of its rather heavy initial investment it still retains its charm in strong competitive industrial applications. In the world today, around 25% of the motors manufactured are dc motors.

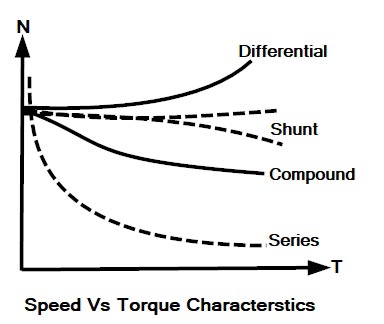

Speed Torque Characteristic

One of the important properties of DC motor is its speed-torque characteristic. Ideally, when the voltage is connected to the motor, it must provide constant torque to accelerate the rotor and when the required speed is reached the torque must become zero. These are also called mechanical characteristics. The nature of these characteristics can easily be obtained by using speed and torque equations.

These characteristics also show how much torque can be developed at a given speed to stay within the rating of the drive. Hence speed-torque characteristics play a very important role in selecting a type of motor for a particular application.

Note:- The availability and economics of a dc power is the deciding factor along with the motor characteristics.

In a dc series motor the starting torque is very high, up to five times the full-load torque. It may be interesting to note that the maximum torque in a dc motor is limited by commutation and not, as with other motors, by heating. Speed regulation of a dc series motor can be varied widely. For drives requiring a very high starting torque, such as hoists, cranes, bridges, battery-powered vehicles and traction-type loads, the series dc motor is the obvious choice. Speed control is by armature resistance control.

Compound motor characteristics depend naturally upon the degree of compounding. The shunt field of course restricts the no-load speed to a safe value. Its main competitor is the squirrel-cage high-slip induction motet A compound motor has a considerably higher starting torque compared to a shunt motor and possesses a drooping speed-load characteristic. Compound dc motors are used for pulsating loads needing flywheel action, plunger pumps, shears, conveyors, crushers, bending rolls, punch presses, hoists, rolling mill, planning. etc.

A dc shunt motor has a medium starting torque. The speed regulation is about 5-15%. It is used essentially for constant speed applications requiring medium starting torques, such as centrifugal pumps, fans, blowers, conveyors, machine tools, printing presses, etc. Owing to the relative simplicity, cheapness, and ruggedness of the squirrel cage induction motor, the shunt motor is less preferred for constant-speed drives except at low speeds. At low speeds, dc shunt motors are comparable with synchronous motors. The outstanding feature of a dc shunt motor, however, is its superb wide range flexible speed control above and below the base speed using solid-state controlled rectifiers.

In general, whenever a decision is to be made for a choice of a suitable motor for a given application, it is necessary to make the specific, analytic, economic, and technical comparison of all practical choices. Finally, it should be mentioned to the credit of a dc machine that it still remains the most versatile, flexible, easily controllable energy conversion device whose demand and need would continue to be felt in industries in the future for various applications discussed above.