Ques 31. The characteristics of the drive for crane hoisting and lowering is

- Smooth Movement

- Precise control

- Fast speed control

- All of the above

Answer.4. All of the above Explanation:- Hoists Hoists are a means of transporting materials or passengers vertically by means of a moving level platform. Materials hoist come in basically two forms i.e static and mobile models. The hoist can be driven by petrol, diesel, or electric motor and can be of a cantilever or enclosed variety. Crane A crane is the type of machine mainly used for handling heavy loads in different industry branches: metallurgy, paper, and cement industry. By the construction, cranes are divided into the overhead and gantry cranes Torque and power requirements for crane and Hoist drives Speed control is an essential feature in crane drives. It is required for allowing soft starting and stopping of the travel motions for enabling its correct positioning of the load. For the lifting drive the speed control in a wide speed range, from zero to nominal values, is required. Because of the precision when raising and lowering load, the possibility of working at a very low speed and hold a load at the standstill is required, without using the mechanical brakes. The torque and power that have to be delivered by the drive may be obtained from the torque versus speed characteristic from the load (so-called mechanical characteristics) and the differential equation of motion. During acceleration, kinetic energy is stored in the system. To stop the crane, this energy must be absorbed by the drive. The acceleration and retardation must be uniform. For exact positioning of loads creep speeds must be possible. The motion of crane is in all three dimensions. The drive must have high speeds in both the directions horizontal and vertical. The speed must be constant while lowering the loads. Mechanical braking must be available in the emergency. Due to the heavy inrush of current at starts, fluctuations in supply voltage are possible. The drive motor must be capable of withstanding such fluctuations. Crane hooks have to be moved in three dimensions in space: two in a horizontal plane and a vertical hoist motion. The characteristics of long travel and cross travel motions are: Hoist motion: This is required to lift and put down loads without damage. The characteristics of this motion therefore are: The nature of duty cycle and conditions under which it has to work forms the basis of the requirements of the crane. In steel plants, the cranes to be used must satisfy the following: Among the d.c. motors, the series motors, and cumulative compound motors are most preferred for crane operations. The motors have good starting torque, high torque capacity at light loads, the simple arrangement of braking, electric braking at low speeds is possible. The only disadvantage is that the motors are less stable while the regenerative braking. So additional stabilizing circuits are necessary. Advances made in the technology of solid-state devices have enabled the use of thyristor converters and choppers for driving the d.c. motors used in cranes and hoists with good accuracy, reliability, and efficiency. Ward Leonard system is commonly employed for elevators, hoists, and main drive in steel mills, as this method can give unlimited speed control in either direction. Since the generator voltage can be varied gradually from zero, no extra starting equipment is required to start up the main motor smoothly. In SLIP RING induction motor the ends of the rotor windings are externally connected by a variable rheostat (resistance is varied in order to give it proper starting and running current). So more the resistance, more the torque. When we add resistance to the rotor the torque is high, the slip is high and the current is reduced.

Ques 32. The capacity of a crane is expressed in terms of

- Span

- Type of drives

- Tonnes

- None of the above

Answer 3. Tonnes

Ques 33. The traveling speed of the crane varies from

- 1 to 2.5 m/s

- 5 to 10 m/s

- 10 to 20 m/s

- 25 to 40 m/s

Answer A. 1 to 2.5 m/s Explanation:- The crane is required for allowing soft starting and stopping of the travel motions for enabling its correct positioning of the load. Hence whenever the crane has loaded the speed of the crane is between 3.5 to 10 km i.e 1 to 2.7 m/s However in the special case when the crane is at light load or no load the speed of cranes is 20 km/hr and above i.e 5.55 m/s above.

Ques 34. In overhead traveling cranes

- Continuous duty Motor is used

- Slow speed motor is preferred

- Short time rated motor is preferred

- Intermittent periodic Motor is preferred

Answer. 4. Intermittent periodic Motor is preferred Explanation:- Electric cranes require huge torques for short time. It is desired to specify a motor with pull out torque of 275 to 30090 of rated full load torque based on 40% duty rating. The motor of a steelworks duty crane must be designed with the lowest moment of inertia and high pull out torque to meet the need for repetitive operations. Motors with lower synchronous speeds are best suited. Duty cycle For crane and hoist motors, duty types S3, S4 and S5 as specified in IS:325-1970 are generally applicable. The motor should be designed for any of the duty factors, e.g. 15, 25, 40 and 60%. The duty factors for different types of cranes have been standardized depending upon operation, e.g. in steel industries, the duty factors are: Hoisting 60%; Traversing 60%; Travelling 60%; Siewing 40%. Indian Electrical Manufacturers’ Association (IEMA) has brought out standards on crane duty motors in which an attempt is made to list the outputs against the IEC frames for S3 (6 starts/hour), S4 and S5 (150 and 300 starts/hour). Slip ring induction motors are widely used for crane duties where squirrel cage motors are not suitable, where speed control is necessary, etc. With the development of thyristors, the use of DC motors is also increasing.

Ques 35. 15 minutes rated Motor is suitable for

- Light duty cranes

- Medium duty cranes

- Heavy duty cranes

- All of the above

Answer 1. Light Duty cranes Explanation:- Classification of Cranes Cranes for foundries, steel works and power stations generally require creep speeds on hoist motion for accurate load spotting. Cranes for material handling plants should be designed for higher operating speeds and duty cycles than any general workshop cranes. For steel works, cranes must be selected to operate round the clock with higher operating speeds and low creep speed. The classification of various types of cranes is mainly based on the following factors: (i) Nature of the work it has to perform, e.g. handling of hot ladles, for transport of ingots, for the handling of raw materials, etc. (ii) The duty factor: This is the time it has to work compared to the total working period of the shop and frequency of starting the crane. In a steel plant, they may be divided into 4 groups:

Ques 36. Heavy Duty cranes are used in

- Heavy engineering workshop

- Steel plants

- Ore handling plants

- All of the above

Answer.4. All of the above

Explanation:-

Ques 37. 1/2 hour rated motors are used for

- Light duty cranes

- Medium duty cranes

- Heavy duty cranes

- Continous Duty

Answer 2. Medium duty cranes Explanation:- An essential requirement of Medium duty crane motor is to develop high starting tot and should be able to withstand a medium number of switching operations. Besides, these motors are provided with special electro-mechanical brakes, which by means of springs, are made to hold the load as soon as the supply fails. On the restoration of supply, the solenoid across the terminals of the motor gets energized and brakes are released. Such motors are 1/2 hr or one hour rated. Interestingly the term short time rating is defined as:– The output which a motor can give for a specified period (e.g. 1 hr, 1/2 hr etc. ) without exceeding a specified temperature, the motor is assumed to be short time rated motor.

Ques 38. Which of the following drive can be used for derricks and winches?

- Pole changing squirrel cage motors

- AC slip-ring motors with variable resistance

- DC motors with Ward Leonard control

- Any of the above

Answer.4. Any of the above Explanation:- A derrick is a lifting device composed at the minimum of one guyed mast (a tall thin vertical structure that depends on guy lines for stability.) which may be articulated over a load by adjusting its guys. A winch is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust the “tension” of a rope or wire rope (also called “cable” or “wire cable”). Both the machine working is similar to the crane machine hence the motor used in this type of machine is also similar. e.g:- Ward Leonard motor method, Slip ring induction Motor, DC compound motor, DC series Motor, Squirrel cage induction Motor with pole changing.

Ques 39. The advantage of 3-speed A.C cage Motor as compared to simple squirrel cage induction motor used in winches are

- Low starting Loss

- Low accelerating Loss

- Both 1 and 2

- None of the above

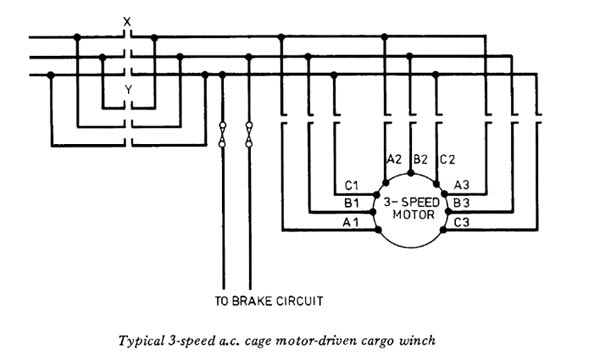

Answer. 3. Both 1 and 2 Explanation:- Three-speed a.c. cage motor-driven cargo winch Present day cargo winches must be able to meet high cargo handling rates involving frequent starting and stopping. To overcome the inherent disadvantages associated with direct switching cage motors a specially designed dual stator/rotor low inertia, high torque motor is necessary. This minimizes the starting and accelerating losses which are responsible for a large proportion of the overall losses and subsequent heat generated. The three-speed motor has two stators and three contractors; a low-speed stator with a 24-pole winding controlled by contactor 1 and a medium/ high-speed stator with two independent windings, one wound for 8 poles and the other for 4 poles controlled by medium speed contactor 2 and high-speed contactor 3. All windings are star connected. These are in turn fed by reversing contactors x and y. To run the motor through its speed range, first the low-speed contactor 1 is closed and then the forward or reverse contactor is energized and the motor will run at low speed, the electromagnetic brake being simultaneously released by an additional contactor. As the controller is moved to steps 2 and 3 the motor accelerates first to medium speed and then to high speed. To make the system foolproof, much interlocking is provided and, in addition, electrical deceleration is provided to reduce wear on the brake shoes. Auxiliary contacts on each succeeding contactor open to trip out the preceding contractor but each succeeding contractor comes under the control of a timing device to ensure the current peak which occurs while accelerating has died down before the next acceleration takes place.

Ques 40. A pole changing type squirrel cage motor used in derricks has four, eight and twenty-four poles. In this, the medium speed is used for

- Lifting

- Hoisting

- Lowering

- Landing the load

Answer. 1. Lifting Explanation:- A crane is a type of machine, generally equipped with a hoist rope, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. Lift speed is usually based on the height the product will be lifted, the frequency of lifts, and how delicately the product must be set down (this can also be accomplished with 2 speed or variable speed). This means that if you are lifting a near-capacity load with a 30-ton crane, the crane will operate at a nominal speed (medium speed) and, once the hook is empty, will return at a faster speed to pick up the next load. This increases your crane’s average speed and reduces average hoist cycle time to raise productivity in a given work period