Ques.11. Which locomotive has the highest operational availability?

- Diesel

- Electric

- Steam

- All of the above

Answer.2. Electric Explanation:- Electric Locomotive:- An electric locomotive requires much less time for maintenance and repairs than a steam locomotive and such vehicles can, if desired, be kept in service for 95% or more. Diesel Locomotive:- It is available for hauling for about 90% of its working days. Steam locomotive:- It is available for hauling work for about 60% of its working days, the remaining 40% is spent in preparing for service, maintenance, and overhaul.

Ques.12. A drive suitable for mines where explosive gas exist is

- Steam engine

- Battery locomotive

- Both 1 and 2

- None of the above

Answer.2. Battery locomotive Explanation:- Safety is very important in coal mine production. Mine battery-electric locomotive is a major transport device for coal mine production, mainly driven by DC motor at present. Aiming at common faults of the lead-acid storage battery in mine battery locomotive, including the emission of highly flammable hydrogen gas during battery charging. Modern battery locomotive uses advanced switching power supply technology and intelligent control technology, not only improving charging efficiency but enhancing charging reliability and not producing any harmful gases in the charging process. The charger has characteristics such as lightweight, small volume, high efficiency, good control performance, and protection functions for over-voltage, under-voltage, over current, overload, battery voltage detection, and polarity, at the same time it achieves the whole process of tracking management and health diagnosis for equipment use and maintenance to provide quick and efficient material guarantee for coal mine safety production. The battery locomotive has similar advantages of mobility as the diesel counterpart. Frames, buffer gear, braking equipment, and to a degree, wheels, and axles are similar in construction to those employed on the diesel locomotive, but there the similarity ends. This form of the locomotive also has its advantages and its disadvantages. The fundamental advantage of the battery locomotive is that it is clean, silent, relatively pollution Free in operation, reliable and requires a low order of maintenance. Initial costs may be higher than a diesel locomotive because, in addition to the locomotive with its battery, a standbys battery with its associated charger is required. However, its operation and maintenance costs may well be lower.

Ques.13. A diesel submarine while moving underwater, is provided driving power through

- Diesel engines

- Steam turbine

- Gas turbine

- Batteries

Answer.1. Diesel engines Explanation:- A submarine is a type of ship that is designed to operate under backwater for lengthy periods. A diesel submarine is a very good example of a hybrid vehicle. Most diesel submarines have two or more diesel engines. The diesel engines can run propellers or they can run generators that recharge a very large battery. Because of the exhaust gases and smoke and the need for plenty of air for the diesel engines to run, they could not operate while the boat was submerged. Even if some sort of snorkel system made it possible to run the engines, pulling in air and venting smoke such a snorkel was actually employed in some submarines after World War II they still made plenty of noise and black smoke, making detection by surface craft easy. Only battery power could be used while submerged, and batteries could not be charged while underwater. The submarine had to remain on the surface while charging, and that could take a while to get a full charge. Once the batteries are fully charged the sub can head underwater. Being submerged with little or no battery power remaining could be catastrophic. That was only one thing a sub crew had to watch continually and calculate accurately so as not to run out of juice. Battery operation is the only way a diesel sub can actually submerge. In the fully submerged condition, it is the stored electrical energy of the batteries that meet the power demands of the vessel. As well as providing the propulsive power, the batteries also have to provide power for the operation of sensors, weapons, and auxiliary machinery and those for habitability, ventilation, of the crew.

Ques.14. Which motor is used in tramways?

- Capacitor start the motor

- Single Phase synchronous motor

- DC series motor

- DC shunt motor

Answer.3. DC series motor Explanation:- In trains or bus, there are many compartments full of passengers & luggage, so during the starting, it requires high starting torque. DC series motor is used for the locomotive because it has very high starting torque and variable speed. DC series motors will have a starting torque as high as 500% compared to the normal operating torque. The DC series motor has long been the most common type of traction motor for railroad service in both electric and diesel-electric locomotives because of its superior operating characteristics. As the load on the motor increases, the field strength automatically increases, and the result is an increase in torque with a decrease in speed. Conversely, the speed increases as the load decreases. Consequently, the series motor tends to adjust itself readily to the varying tractive effort required to accelerate and power a train.

Ques.15. Long-distance railways use

- 200 V DC

- 25 kV Single phase AC

- 25 kV Two-phase AC

- 25 kV Three-phase AC

Answer.2. 25 kV Single phase AC Explanation:- The 25 kV standard at 50 hertz was introduced in 1923 in Hungary and adopted as an international standard in 1950. Suppose that power is to be transmitted from a power station to a home or a factory. Since power is the product of current and voltage (P = V x I), a given amount of power can be transmitted either at high voltage and low current or at low voltage and high current. The cables that transmit the power have resistance, and therefore some of the power is bound to be wasted by producing heat in the cables as the current flows through them. If the resistance of the cables is R. the heat energy produced in time t when a current I is flowing through them is I2Rt. Thus the amount of energy that is wasted is proportional to the square of the current in the cables(Ploss=I2R). The most efficient way to transmit power is therefore at high voltage and low current. This is known as high tension transmission. When resistance is low, energy losses are low also. So that faster control for minimizing the arcing of contacts & maintained by a high level of the protective scheme. The second advantage of high voltage/low current transmission of electrical power is that low currents require thinner and therefore cheaper cables. A disadvantage is the high cost of the substantial insulation needed when employing high voltages. Let’s say R = 10 ohms If you try to send 100W over at 100V, you need to use 1A. Then the power lost in the cable is I2 x R = 12 x 10 = 10W. If you try to send the same 100W over at 1000V, you need to use 0.1A. Then the power lost in the cable is 0.12 x 10 = 0.1W The higher the voltage, the greater is the power it can give. So the transmission lines, railway power lines use very high voltages with thinner copper wires can be used, which is cheaper and apart from that transmission losses also will be reduced.Why is electrical energy transmitted at high voltage and low current?

Ques.16. The coefficient of adhesion is

- Same on ac and dc traction systems

- High in case of dc traction and low in ac traction

- Low in case of dc traction and high in ac traction

- None of the above

Answer.3. Low in case of dc traction and high in ac traction Explanation:- When two solid surfaces are brought into contact, a finite normal force is needed to pull the two solids apart. This force is known as the force of adhesion or simply adhesion. Thus, adhesion is the phenomenon that occurs when two surfaces are pressed together either under a normal load or under a combined normal and shear load. The coefficient of adhesion is defined as the ratio of tractive effort required to propel the wheel of a locomotive to its adhesive weight. Adhesion traction is the friction between the drive wheels and the steel rail. Adhesion is caused by friction, with the maximum tangential force produced by a driving wheel before slipping given by: Fmax= coefficient of friction × Weight on wheel The word “adhesion”, means the coefficient of friction required between the driving wheels and the running surface to carry the tractive effort of interest. A vehicle is said to be “motored to adhesion” when the traction motors will rate continuously all the tractive effort that the maximum available adhesion will support. The available adhesion depends on the weather and many other factors; it always decreases as speed increases. With DC. locomotives, since the dc. motors are light, it is desirable to place the whole of the locomotive weight on driving wheels to obtain the required tractive effort whereas, with A.C locomotives since the weight of electric equipment is higher, the required tractive effort can be obtained by placing only a portion of the weight on the driving wheels and supporting the rest on the trailing axels. For rapid transit cars having every axle motored, about 5% adhesion is required for each 1 mph/see of accelerating rate. A D.C locomotive can typically attain 28-30% adhesion and an ac locomotive in the range of 33-35% adhesion on the clean, straight rail. On rubber-tired vehicles, adhesion is not a factor of concern.

Ques.17. The coefficient of adhesion is highest when

- The rails are dry

- The rails are oiled

- The rails are wet with dew

- The rails are dusty

Answer.1. The rails are dry Explanation:- The value of the coefficient of adhesion is affected by the speed of the train and the conditions of the rails The higher the speed, the smaller is the coefficient of adhesion. If the rails are wet and greasy, the coefficient of Adhesion is much lower as compared to when they are dry and sandy.

Ques.18. Which of the following braking system is costly?

- Vacuum braking on steam locomotives

- Vacuum braking on diesel locomotives

- Regenerative braking on electric locomotives

- All braking systems are equally costly

Answer.3. Regenerative braking on electric locomotives Explanation:- Electric braking In this process of braking, the kinetic energy of the rotating parts of the motor is converted into electrical energy which in turn is dissipated as heat energy in resistance or in sometimes, electrical energy is returned to the supply. Here, no energy is dissipated in brake shoes. Regenerative braking The braking of heavy trains on long down gradients is materially facilitated by the use of regenerative braking, whereby some of the mechanical energy released by the train in its downward progress can be reconverted into electrical energy and returned to the supply system. For this purpose, it must be possible to reconnect the traction motors as generators and control the speed by the braking torque developed. Regeneration is possible with any form of electric traction at the expense of additional weight, cost, and complication. Regeneration has been most successfully employed on locomotives that have to negotiate heavy grades. Regenerative braking is also feasible in heavily loaded urban railways. Regenerative braking can give a significant reduction in overall energy consumption on urban railways, and typical figures of 10-20% are achieved on densely loaded systems. Cost savings due to reduced brake wear can be equal to energy savings. Although the initial cost of electrical braking is high, the maintenance cost is low.

Ques.19. The advantage of electric braking is

- It is instantaneous

- More heat is generated during braking

- It avoids wear of the track

- Motor continues to remain loaded during braking

Answer.3. It avoids wear of the track Explanation:- Advantages of electric braking over the mechanical braking Disadvantages of the electric braking

Ques.20. Braking retardation on suburban trains is

- 0.3 to 0.5 km phps

- 0.5 to 1 km phps

- 3 to 5 km phps

- 30 to 40 km phps

Answer.3. 3 to 5 km phps

Explanation:-

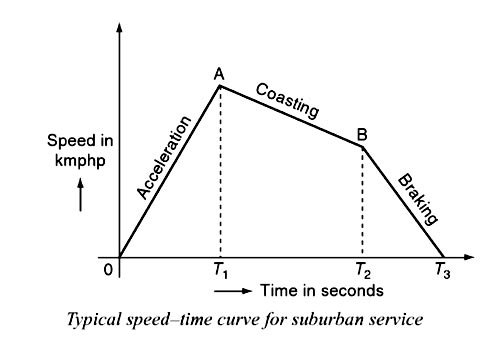

Speed-time curve for suburban service

In suburban service, the distance between two adjacent stops for an electric train is lying between 1 and 8 km. In this service, the distance between stops is more than the urban service and smaller than the mainline service. The typical speed—time curve for suburban service is shown in Fig.

The speed-time curve for urban service consists of three distinct periods they are:

(i) Acceleration.

(ii) Coasting.

(iii) Retardation.

For this service, there is no free-running period. The coasting period is comparatively longer since the distance between two stops is more. The braking or retardation period is comparatively small. It requires relatively high values of acceleration and retardation. Typical acceleration and retardation values are Iying between 1.5 and 4 kmph and 3 and 4 kmph, respectively.