Ques.11. In “argon arc welding” the electrode is made of

- Carbon

- Steel

- Tungsten

- No electrode is needed

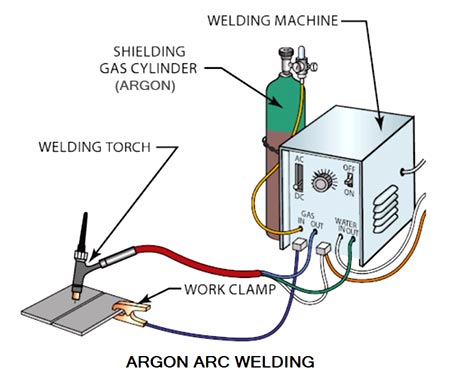

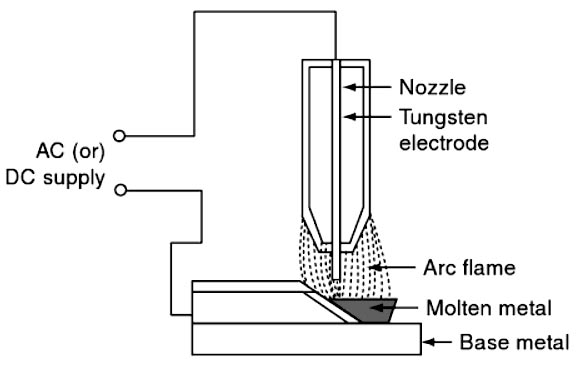

Answer.3. Tungsten Explanation:- In “argon arc welding” the electrode is made of tungsten. The argon arc welding process enables aluminum, magnesium, stainless steel, and copper to be fusion welded without the use of a flux. The arc burns within a shroud or shield of an inert gas such as argon which is one of the rare gases present in the atmosphere. The equipment consists of three main items: a torch, electrical supply, and argon. The torch is constructed of a non-conductive material with a shield surrounding the tungsten electrode made of a ceramic material. The torch may be either water or air-cooled; for sets up to 300 amp it is water-cooled, but below 150 amp air-cooling is sufficient. The cooling of the torch is important in that it prevents the ceramic shield from cracking under intense heat. Different diameter electrodes are required according to the thickness of the material being welded. For the welding of aluminum, aluminum alloys, and magnesium alloys, a.c. equipment is used, while d.c. equipment is used for stainless steels, nickel-chrome alloys, and copper, the torch being connected to negative polarity. When welding with the argon arc, the tungsten electrode must not be allowed to touch the workpiece, for, if contact is made, contamination of the electrode will result. To overcome the necessity of striking the arc without resorting to contacting with the metal to be welded, a high-frequency current is superimposed upon the welding current, which has the effect of causing high voltage pulses at the electrode tip, sufficient to cause an arc between the workpiece and the electrode without direct contact. Since the electrode does not melt, an extra welding rod is usually required for the supply of material. Advantages ApplicationsArgon Arc Welding

Ques.12. In argon arc welding the purpose of using argon is

- To prevent oxidation of metal by coming in contact with the oxygen of the air

- To create an inert atmosphere around the job to be welded

- To obviate the necessity for using flux

- All of the above

Answer.4. All of the above Explanation:- In the argon arc welding process argon is blown around the arc and onto the weld through the welding gun nozzle. As argon is chemically inert, the molten metal is protected from the action of the atmosphere by an envelope of chemically reducing or inert gas. As molten metal has an affinity for oxygen and nitrogen if exposed to the atmosphere, thereby forming their oxides and nitrides, which makes weld leaky and brittle. Thus, several methods of shielding have been employed. With the use of flux coating electrodes or by pumping, the inert gases around the arc produce a slag that floats on the top of the molten metal and produces an envelope of inert gas around the arc and the weld. Therefore the arc burns within a shroud or shield of an inert gas such as argon which is one of the rare gases present in the atmosphere. Argon is an inert gas, it has no taste, nor smell is non-toxic, does not burn or support combustion and does not readily combine chemically with other elements. Thus, by excluding the arc and welding zone from the atmosphere by this inert gas shield, oxidation and the formation of nitrides are prevented.

Ques.13. Steel rails are welded by

- Resistance welding

- Thermit Welding

- Argon arc welding

- Gas welding

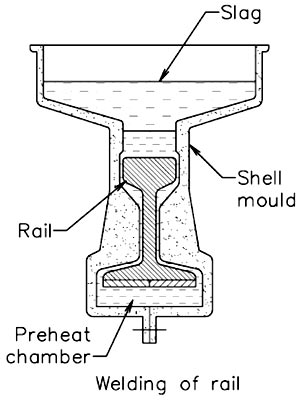

Answer.2. Thermit Welding Explanation:- Thermit welding is a process that produces joints of metals by heating them with superheated molten metal -from an alumino-thermic reaction between a metal oxide and aluminum. Filler metal is obtained from the liquid metal formed by the reaction. The process had its beginning at the end of the l9th century, and it is used presently to join rails in railway track, thick plates, repair of broken machine parts, joining of heavy copper electric conductors, etc. Principle of operation Thermit welding makes use of the heat supplied by the exothermic reaction involving the combustion of thermit, which is a mixture of powdered aluminum (20% to 22%) and iron oxide (for steel) in the form of a scale (80% to 78%) obtained during steel rolling process. The thermit for steel burns according to the following reaction: Fe2O3 + 2Al = Al2O3 + 2Fe + 185 kcal per mol The reaction will start and proceed if the thermit is preheated at least in one point of it to approximately 1200 °C by means of a primer or ignition powder. The thermite reaction is non-explosive and requires a time of less than one minute for completion, regardless of quantity. To start the reaction, a special ignition powder or ignition rod is required; both can be ignited by using a regular matchbox. The ignition powder or rod will produce enough heat to raise the thermite powder in contact with the rod to the powder’s ignition temperature. Applications Some of the important applications of thermite welding are given below:Thermite Welding

Ques.14. In gas welding the gases used are

- Oxygen and nitrogen

- Argon and Helium

- Helium and carbon dioxide

- Acetylene and oxygen

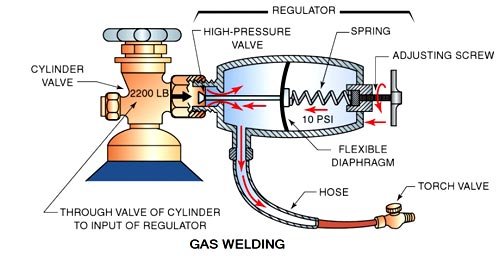

Answer.4. Acetylene and oxygen Explanation:- In gas welding, the heat generated by the combustion of various gases in a stream of oxygen is used to melt the welding area and filler metal. The most popular gas-welding process is oxy-acetylene welding. This is a fusion welding process used to join thin metallic sheets or pieces. Since oxy-acetylene welding is very popular, this method of welding is also known as gas welding. The use of acetylene and oxygen made it possible to produce a comparatively high flame temperature, 3 1 00°C, which is higher than that of other hydrocarbon-based gases. The torch became the most important tool for welding and cutting of steel. The oxygen that we use in the welding industry, is compressed to very high pressure of up to 20000 kPa in the cylinders. Acetylene is a colorless hydrocarbon gas that burns very easily. The symbol that we use for acetylene is C2H2, which tells us that the gas is made up of two carbon atoms (C) and two hydrogen atoms. Since hydrogen is the lightest element there is, hydrogen gas is highly flammable and it will burn fiercely or even explode in oxygen. Under certain conditions, it will self-ignite or spontaneously combust. This is why acetylene is such a good gas to use for welding.Gas welding

Ques.15. Steel pipes are manufactured by

- Arc welding

- Thermit welding

- Resistance welding

- Argon arc welding

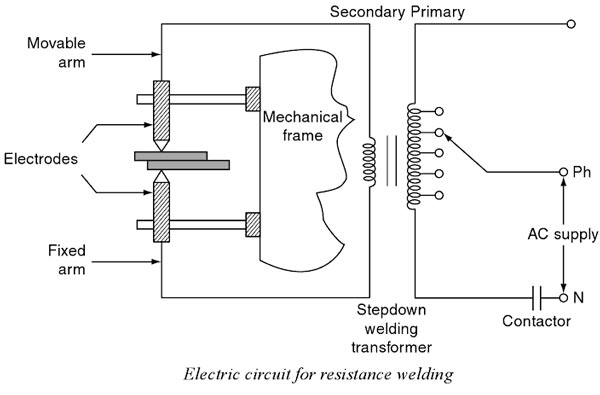

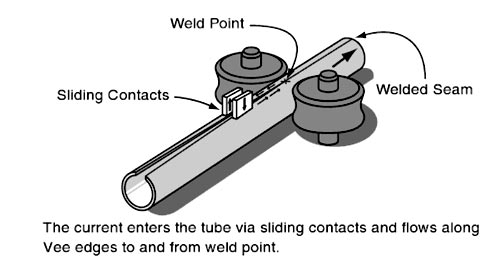

Answer.3. Resistance welding Explanation:- RESISTANCE WELDING Resistance welding is the process of joining two metals together by the heat produced due to the resistance offered to the flow of electric current at the junctions of two metals. The heat produced by the resistance to the flow of current is given by: H=l2Rt, Where I is the current through the electrodes, R is the contact resistance of the interface, t is the time for which current flows. Here, the total resistance offered to the flow of current is made up of: In this process of welding, the heat developed at the contact area between the pieces to be welded reduces the metal to plastic state or liquid state, then the pieces are pressed under high mechanical pressure to complete the weld. The electrical voltage input to the welding varies between 4 and 12 V depending upon the area, thickness, composition, etc. and usually power ranges from about 60 to 180 W for each sq mm of the area. The electric resistance welding and electric fusion welding are the most common methods used to convert flat-rolled steel bars plates, sheets, and Strips into tubular products. Electric resistance welding (ERW) is performed without filler material. The flat strip, with edges previously trimmed to provide a clean, even surface for welding, is formed progressively into a tubular shape as it travels through a series of rolls. Welding is then affected by the application of heat and pressure. The welding heat for the tubular edges is generated by resistance to the flow of an electric current, which can be introduced through electrodes or by induction.

Ques.16. Which of the following welding is different from the remaining?

- Spot welding

- Seam welding

- Butt welding

- Argon arc welding

Answer.4. Argon arc welding Explanation:- Spot welding, Seam welding, Butt welding are part of the resistance welding method while argon arc welding is a gas welding method

Ques.17. Two 3 mm thick mild steel sheets are to be welded. The electrode of 18, 16, 3 and 10 Nos are available which one would you select?

- No: 10

- No: 3

- No: 16

- No: 18

Answer.2. 3 Explanation:- The welding wire or rod used as filler material in gas welding should have a chemical composition similar to that of the base metal. The welding rod diameter, d = t/2 + 1 mm (app.), where t = thickness of the base metal, mm. d = 3/2 + 1 = 2.5 mm Note:- The size of the electrode generally depends on the thickness of the section you are welding: the thicker the section, the larger the electrode required. In the case of the light sheets, the electrode size used is generally slightly larger than the work being welded. This means that if a 2.0-mm sheet is being welded, a 2. 5-mm diameter electrode is the recommended size.

Ques.18. What is an example of plastic welding?

- Gas Welding

- Resistance welding

- Thermit welding without pressure

- None of these

Answer.2. Resistance welding Explanation:- There are two main types of the welding process. They are (a) Plastic weldings (b) Fusion welding, In plastic welding & metal, pieces are heated to a plastic state. They are praised together to make the joint. Plastic welding is also known as pressure welding. Electric resistance welding such as spot welding is an example of plastic welding. In fusion welding, the metal at the joint is heated to the molten state. Then it is allowed to solidify. Pressure is not applied in this welding process. So it is known as non-pressure welds. Gas welding and electric arc welding are examples of fusion welding.

Ques.19. Gray iron is usually welded by

- Arc welding

- Gas welding

- TIG welding

- MIG welding

Answer.1. Arc welding Explanation:- Gray iron is usually welded by Arc welding Gray cast irons are generally not weldable because they contain a large amount of carbon and silicon carbon in the range of 2% to 4% and silicon from 0.5% to 2%. These make the weal zone very brittle, which eventually cracks. The weldability of cast iron also depends on the distribution of the carbon and the kind of microstructure that develops on cooling. When such casting fractures, repair by waddling is frequently attempted. This again increases the risk of getting additional cracks. To minimize this chance, a good welding method such as arc welding with high nickel filler metal is used. The procedure for arc welding involves preheating castings to a temperature of about 700°F, then welding with minimum weld size followed by a slow cool to room temperature and shot peening of the deposit. It is then tempered room temperature and shot peening of the deposit. It is then tempered at about 600°F for a sufficient length of time. Gray iron class 20 is generally easier to weld than class 50. If required, all gray cast irons can be welded due to the fact that relatively very little is demanded of this material in terms of mechanical properties after welding. Most gray irons are brittle and relatively weak, and service stresses are mainly compressive. Hence, there is no need for high-strength weld deposits.

Ques.20. In ultrasonic welding, the frequency range is generally

- 100 – 4000 cps

- 4000-20000 cps

- 20,000-40,000 cps

- 80,000-200,000 cps

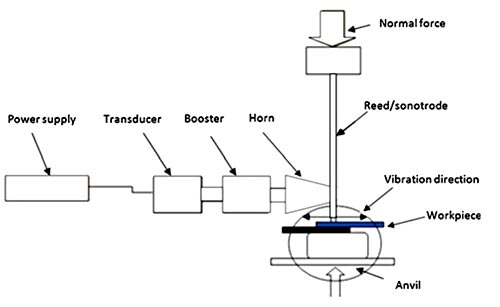

Answer.3. 20,000-40,000 cps Explanation:- Ultrasonic metal welding was invented in Germany during the Second World War. It is a solid-state process in which two parts are welded by the application of ultrasonic vibrations under moderate pressure. Little or no heat is applied and the material reaches near to 50 % of its melting temperature. This process permits the welding of thin to thick sections of materials with lower pressures than used in fused deposition or static press welding. Every ultrasonic unit contains the following four elements: Applications:- The success of ultrasonic welding lies in the fact that the process is very fast (welding times are approximately 1 s), the equipment is compact, the process can be readily automated, and consistently acceptable weld quality can be produced. Ultrasonic welding is commonly used to join components in the automotive, toy, domestic appliance, and packaging industries. It is also the method of choice when welding many medical plastic components. The only limitation is that large parts cannot be welded using this method.