Single phase Induction Motor MCQ | Objective Type Question of Single phase Induction Motor MCQ

Ques 1. In a split-phase motor, the running winding should have

- High resistance and low inductance

- High resistance and High inductance

- Low resistance and high inductance

- Low resistance and low inductance

Explanation:

- In order to self-start a single-phase induction motor one must create a rotating magnetic field on the stator. Therefore split phase motor has two winding one is starting winding and the other is main winding or running winding.

- The starting winding has fewer turns and a small diameter, therefore, it has high resistance and low inductance.

- The running winding has a heavier wire of more turns, therefore, it has low resistance and high inductance.

- As we know that for high inductance current lags behind voltage by a large angle and for high resistance, the current is almost in phase with the voltage.

- Therefore for starting winding the current lags behind the supply voltage by an angle of 15 degrees while for running winding the current lags behind voltage about an angle of 40 degrees.

- This difference in phase angle creates a phase delay in the rotating magnetic field that allows the motor to start otherwise without the phase difference the motor will oscillate in the standstill position.

Ques 2. If the capacitor of a single-phase motor is short-circuited

- The motor will not start

- The motor will run in the same direction at a reduced speed

- The motor will run in the reverse direction

- None of the above

Explanation:

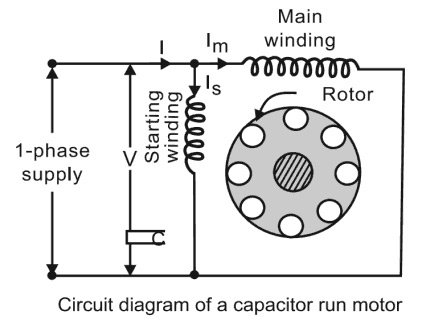

Capacitor motors are split-phase motors with a capacitor added to the auxiliary start winding, main run winding, or both to improve the operating torque characteristics of the motor by causing a greater phase shift in the current between the main and auxiliary start windings.

The capacitor limits the starting surge current to a lower value than is developed by the standard split-phase motor. When the capacitor is short-circuited high inrush current will flow in the winding which may burn the starting winding of a single-phase induction motor.

If the capacitor is short-circuited, there will be 0 starting torque, and as a single-phase induction motor is n0t self-starting, Therefore the motor will not start.

Ques 3. In a split-phase motor

- Both starting and running windings are connected through a centrifugal switch

- Centrifugal switch is used to control supply voltage

- The running winding is connected through a centrifugal switch

- The starting winding is connected through a centrifugal switch

Explanation:

Split-Phase Induction Motor

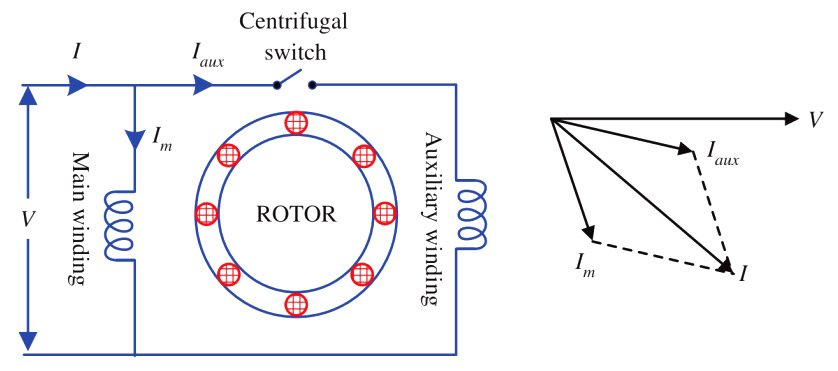

- The main components of the split-phase motor include main winding, auxiliary winding, and a centrifugal switch.

- This is the simplest way to establish a rotating magnetic field with two windings in the same stator core.

- The auxiliary or starting winding has a series of resistance that makes its impedance highly resistant.

- It is not the same winding as the main winding but has fewer turns of a much smaller diameter than the main winding.

- This will reduce the voltage lagging of the starting current.

- The main winding is inductive in nature to lag the voltage by a certain angle. This winding is designed to operate at synchronous speeds of 75% and above.

- These two windings are connected to the input AC supply in parallel.

- Because of the inductive nature, the supply voltage lags at a large angle, with the current induced by the starting winding almost being in phase with the voltage due to its resistive nature. Thus, there is a phase difference between these currents. The resulting current produces a rotating magnetic field and thus the starting torque.

- The centrifugal switch is connected to the starting winding in series.

- When the motor is 75-80% of the synchronous speed, the centrifugal switch is opened mechanically, thereby removing the auxiliary winding. The motor, therefore, only works with the main winding.

Ques 4.Torque developed by a single-phase induction motor at starting is

- Less than the rated torque

- More than the rated torque

- zero

- None of the above

Explanation:

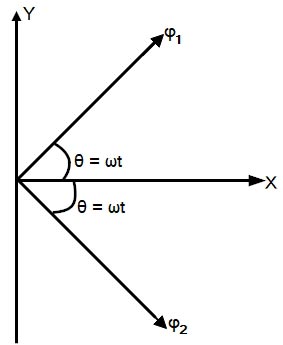

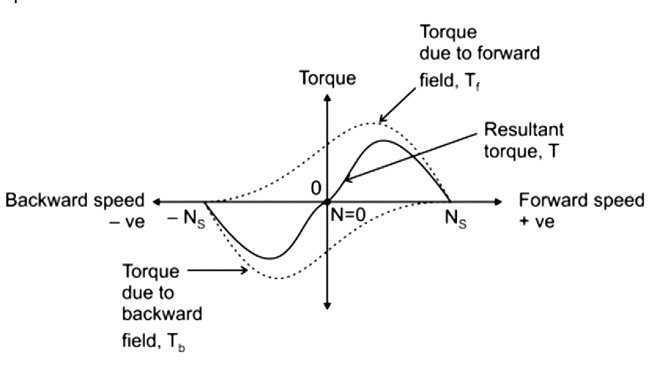

The working principle of an ac machine is primarily “one field following another field”. In the case of a multiphase induction motor, there will be a virtual rotating magnetic field. But considering the case of a single-phase induction motor, it’s only a pulsating field that is produced and not a rotating one. This can also be explained on the basis of ‘DOUBLE REVOLVING FIELD THEORY‘, which is based on Ferraris Principle

As per Ferrari’s principle, the alternating magnetic field produced by the stator can be split into two rotating magnetic fields of half the magnitude and rotating at synchronous speed in opposite directions. When the alternating supply is fed to the stator winding, an alternating flux is developed This flux rotates and cuts the rotor conductors. Due to this, an EMF is induced. As the rotor circuit is closed the current flows through the rotor conductor. This rotor current will cause rotor flux and at any instant, its magnitude is given by,

φs = φm COS ωt

where φm is the maximum flux developed in the motor. According to this theory, the alternating flux φs can be resolved into two components of and φf & φb such that the magnitude of by φf & φb is equal to half the magnitude of φs. Let us assume that φf rotates in a clockwise direction and φb rotates in the anti-clockwise direction.

An emf is induced in the rotor circuit due to each rotating field. If the polarity of the induced emf in the rotor due to φf is taken as positive then emf induced in the rotor due to φb is negative (i.e. in phase opposition). As, at standstill, the slip in either direction is the same (i.e. s = 1), the rotor impedance will also be the same. Thus, the rotor currents are equal, but opposite in phase that is the starting torque developed by each revolving field is the same, with one acting in forward direction and the other acting in the backward direction. Thus, the net torque developed by the motor is zero.

Based on double-revolving field theory, a single-phase induction motor can be visualized as having two rotors revolving in opposite directions with a common stator winding. At standstill, the two rotors develop equal torques in opposite directions and hence the net torque developed is zero.

Ques 5. In a capacitor start and run motors the function of the running capacitor in series with the auxiliary winding is to

- Improve power factor

- Reduce fluctuations in torque

- Increase overload capacity

- To improve torque

Explanation:

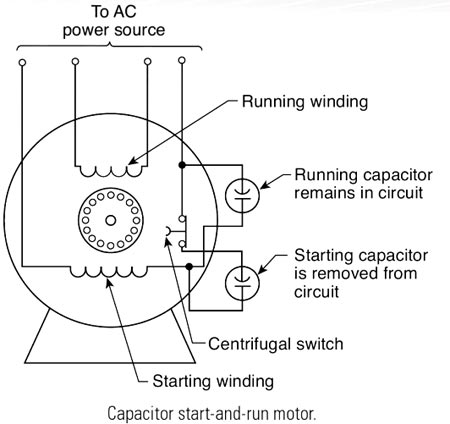

Capacitor start Capacitor run motors

- This type of motor is designed to operate with the start winding and it is series capacitor permanently connected to the supply.

- lt has two capacitors connected in parallel in the start winding circuit for starting purposes.

- A start capacitor stays in the circuit long enough to rapidly bring the motor up to a predetermined speed, which is usually about 75% of the full speed, and is then taken out of the circuit, often by a centrifugal switch that releases at that speed.

- The running capacitor is employed to correct the power factor.

- Run capacitors are designed for continuous duty while the motor is powered, which is why electrolytic capacitors are avoided.

- As a result, this motor has a higher starting torque as well as a higher efficiency. These motors are employed in sizes ranging from 375 W to 7.5 kW. The power factor of these motors is upto 80% to 100%.

Note:-

- Inductive Loads consume Reactive Power and Capacitive Loads deliver Reactive Power.

- The Power Factor Angle is inversely proportional to the Power Factor( reducing the angled gap between the Voltage vector and the Current Vector improved power factor).

- So in a single-phase Induction Motor, a Capacitor Bank is connected, then the Reactive power demand by the Inductive load (Induction Motor) is supplied by the Capacitor Bank, not from the Source.

- Therefore the system reactive power demand is reduced and the Power factor is improved.

Ques 6. Which of the following motor will have a relatively higher power factor?

- Capacitor start motor

- Shaded pole motor

- Capacitor run motor

- Split phase motor

Explanation:

Capacitor Run Motor

- In this motor, the capacitor that is connected in series with the auxiliary winding is not cut out after starting and is left in the circuit all the time. That is the capacitor is used for starting and remains in the circuit during the running conditions.

- This motor is similar to the capacitor start motor except that there is no centrifugal switch.

- The capacitor value is chosen to obtain a nearly 90° phase shift between the currents of main and auxiliary windings around full-load speed.

- This simplifies the construction and decreases the cost because the centrifugal switch is not needed.The power factor, torque pulsation, and efficiency are also improved because the motor runs as a two-phase motor. The motor will run more quickly.

Performance and characteristics:- Starting torque is lower about 50 to 100% of full load torque. Power factor is improved may be about unity. Efficiency is improved to about 75%. It is usually used in fans, room coolers, portable tools and other domestic and commercial electrical appliances.

The main advantages of capacitor run motor are:

- Higher power factor,

- Increased overload capacity of the motor,

- Higher efficiency, and

- Noiseless running of motor.

Ques 7. A centrifugal switch is used to disconnect ‘starting winding when the motor has

- Picked up 10% speed

- Picked up 20% speed

- Picked up 5 – 10% speed

- Picked up 50 – 75% speed

Explanation:

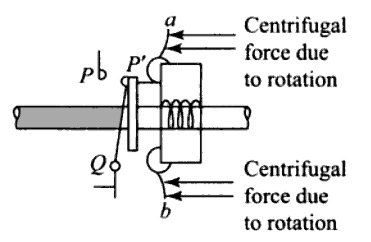

The centrifugal switch is connected in series with the starting winding. The primary function of the starting winding is to produce rotating flux in conjunction with the main winding at the start. When the motor has started and reaches nearly 75% of synchronous speed, it produces its own rotating field from the cross-field effect. The starting winding now has no function to perform and is removed from the circuit by a centrifugally operated switch.

Centrifugal switch working

With the rotor at standstill, the pressure of the spring on the bakelite piece keeps the contacts PP’ closed. The starting winding circuit which is connected across the supply terminals through the centrifugal switch terminals PQ remains closed. The auxiliary winding flux helps the motor to start. As the motor picks up speed, centrifugal force acts on parts a and b. These two parts are pushed backward. They in turn push against the spring pressure, the cup-shaped bakelite piece forward. The spring pressure is such that at about 75 percent of the synchronous speed the centrifugal switch contact points PP’ open, thereby cutting out the auxiliary winding from the supply.

Ques 8. In repulsion motor direction of rotation of the motor

- Same as that of brush shift

- Independent of brush shift

- Opposite to that of brush shift

- None of the above

Explanation:

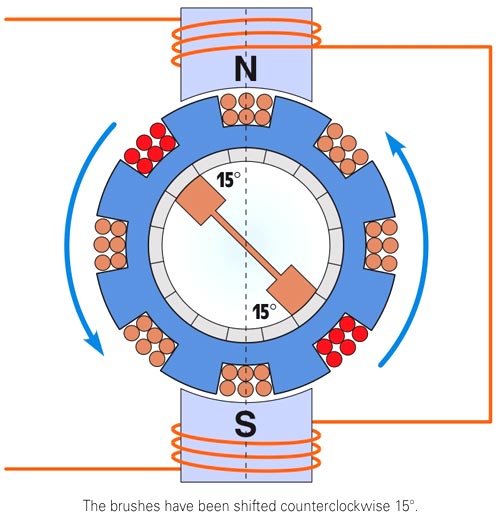

Repulsion motor

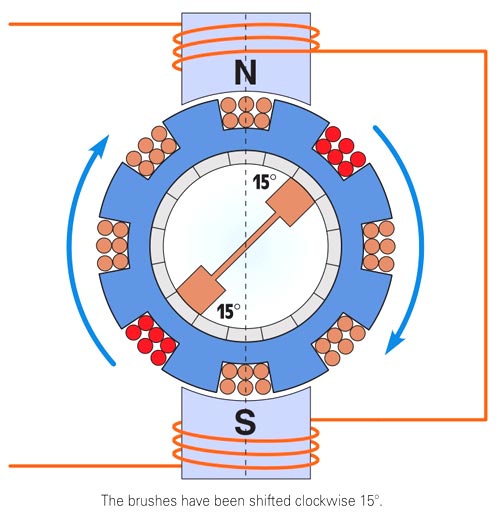

- The direction of rotation is determined by the position of the brushes with respect to the magnetic field of the stator. Hence we can change the direction of the motor by changing the brush positions.

- If the brushes are shifted clockwise from the main magnetic axis, the motor will rotate in a clockwise direction.

- If the brushes are shifted counterclockwise from the main magnetic axis, the motor will rotate in a counter-clockwise direction.

Operating principle of repulsion Motor

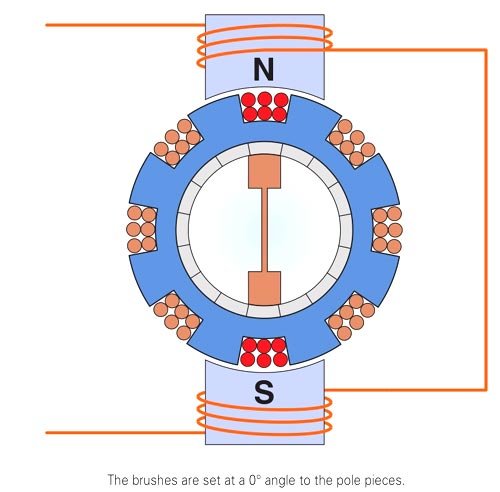

This motor has a wound rotor that functions similarly to a squirrel-cage rotor. It also has a commutator/brush assembly. The brushes are shorted together to produce an effect similar to the shorted conductors of a squirrel-cage rotor. The position of the brush axis determines the amount of torque developed and the direction of rotation of the repulsion motor.

Brush Position of repulsion Motor

The position of the brushes is very important. Maximum torque is developed when the brushes are placed 15° on either side of the pole pieces. When the brushes are position are placed at 90°, a circuit is completed between the coils located at a right angle to the poles. In this position, there is no induced voltage in the armature windings and no torque is produced by the motor.

In Figure, the brushes have been moved to a position so that they are in line with the pole pieces. In this position, a large amount of current flows through the coils directly under the pole pieces. This current produces a magnetic field of the same polarity as the pole piece. Because the magnetic field produced in the armature is at a 0° angle to the magnetic field of the pole piece, no twisting or turning force is developed and the armature does not turn.

When the brushes have been shifted in a clockwise direction so that they are located 15° from the pole piece. The induced voltage in the armature winding produces a magnetic field of the same polarity as the pole piece. The magnetic field of the armature is repelled by the magnetic field of the pole piece, and the armature turns in the clockwise direction.

When the brushes have been shifted counterclockwise to a position 15° from the center of the pole piece. The magnetic field developed in the armature again repels the magnetic field of the pole piece, and the armature turns in the counterclockwise direction.

The direction of armature rotation is determined by the setting of the brushes. The direction of rotation for any type of repulsion motor is changed by setting the brushes 15° on either side of the pole pieces. Repulsion-type motors have the highest starting torque of any single-phase motor.

Ques 9. If a particular application needs high-speed and high starting torque, then which of the following motor will be preferred?

- Shaded pole motor

- Capacitor start motor

- Capacitor run motor

- Universal Motor

Explanation:

A universal motor is a motor that can work with either AC or DC, although it is almost always used with AC. It is sometimes called an AC commutator motor since it has a commutator and brushes like a DC motor. It is a commuted series-wound motor where the stator’s field coils are connected in series with the rotor windings through a commutator. Therefore they produce high starting torque. The universal motor is useful because it can work from the AC mains supply, but has some characteristics of a DC motor. These characteristics are

- High starting torque, which means the motor can reach full speed very quickly.

- High running speed of between 10 000 and 30000 rpm (revolutions per minute).

- It can provide a wide variety of speeds when used with speed controllers.

Universal motors are used in many small appliances and hand-held tools such as food mixers, blenders, vacuum cleaners, drills, grinders, saws, and weed trimmers.

Ques 10. Which of the following motor is used in the mixer?

- Repulsion Motor

- Reluctance Motor

- Hysteresis Motor

- Universal Motor

Explanation:

A universal motor is a motor that can work with either AC or DC, although it is almost always used with AC. It is sometimes called an AC commutator motor since it has a commutator and brushes like a DC motor. It is a commuted series-wound motor where the stator’s field coils are connected in series with the rotor windings through a commutator. Therefore they produce high starting torque. The universal motor is useful because it can work from the AC mains supply, but has some characteristics of a DC motor. These characteristics are

- High starting torque, which means the motor can reach full speed very quickly.

- The high running speed of between 10 000 and 30000 rpm (revolutions per minute).

- It can provide a wide variety of speeds when used with speed controllers.

- The universal motor works on the same principle that the DC series motor works. DC series motor has the characteristics of operating at high speed when there is no load and operating at low speed when the load is applied. It has high starting torque characteristics.

- So it is used in mixers, where initially we put some load at starting.