Ques.41. Which of the following is the most economical method for starting a single-phase motor? (SSC-2016)

- Induction start method

- Capacitor start method

- Resistance start method

- Split phase method

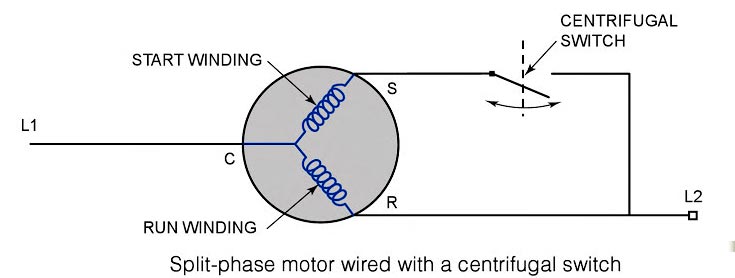

Answer.2. Capacitor start method Explanation:- Various method of starting a single-phase motor is Split-Phase Method When two windings which are displaced electrically by 90°, carry currents with a phase difference of 90°, they will produce a rotating magnetic field. The split-phase method also referred to as the induction-star induction-run (ISIR) method, it has a relatively low starting torque compared with the other single phase motors but more torque than the shaded-pole motor. They range in size from 1/20 horsepower to abort 1/3 horsepower. Split-phase motors get their name from the fact that a single power supply is split between two individual windings — the run and the start — to produce the necessary torque to start the Motor. A split phase induction motor is provided with the main winding and auxiliary or start winding placed in space quadrature and are connected in parallel to a single phase supply. The main winding has a low resistance and high reactance whereas the auxiliary winding has a high resistance and low reactance. The auxiliary winding is effective during the starting of the motor and is disconnected from the supply when the motor attains 75 percent of its synchronous speed. A centrifugal switch, S is used to disconnect the auxiliary winding from the source as shown in Fig. Under the normal running condition, only the main winding is effective. The run winding is energized whenever the motor is energized. This winding has a lower resistance than the start winding, which is only in the circuit long enough to help the motor start. For the motor to start, both the start and run windings must be energized. When both windings are energized, the current flows through each of the windings at a different rate, creating a phase shift. This starting method is cheaper than the capacitor start method Capacitor Start Method The capacitor starts motor employs capacitance to split the phase, rather than resistance. The use of capacitance has many advantages. The fluxes in the two phases can be made to have a phase difference of practically 90°, so that the motor becomes essentially a two-phase motor. Since the currents differ by almost 90°, the starting torque is considerably greater than with the usual split-phase motor of the same rating. The capacitance may remain in the circuit continuously so that the power factor of the motor is very nearly unity. The starting torque can be further increased by increasing the capacitor rating. The cost of the capacitor start method is slightly higher than the split-phase method but due to the high starting torque and high power factor, this method is the most economical method to start a single phase motor. Shaded pole motor method The effect of the shaded coil is to retard in time phase a portion of flux in the poles so that there is a sweeping of the flux across the pole face in the direction of the shading of the coil. The fluxes in the unshaded part of the pole and in the shaded part of the pole cut the rotor conductors and induce currents, which in turn produce a torque sufficient to start the motor. The shaded pole produces a weak starting torque and is used with fractional horsepower motors, such as fan motors and shaving motors. The shaded pole motor is the most simply constructed and therefore, the least expensive of the single-phase motors. Repulsion motor start method A common method of obtaining large starting torque is designing the motor so that on starting, it operates as a repulsion motor and when it attains synchronous speed, it is converted into a single phase induction motor, by some mechanism operated by centrifugal force. It is the most costly method hence this method is replaced by a capacitor start method.

Ques.42. The value of the capacitor in a capacitor start motor controls the (SSC-2016)

- Speed of motor

- Starting torque

- Efficiency

- None of these

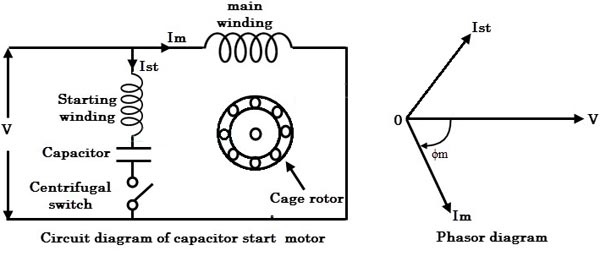

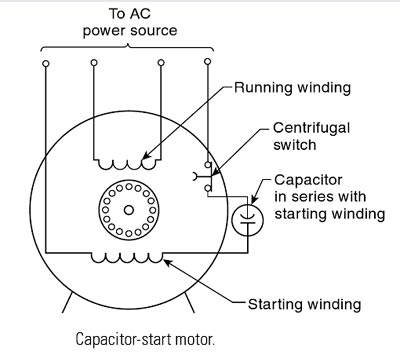

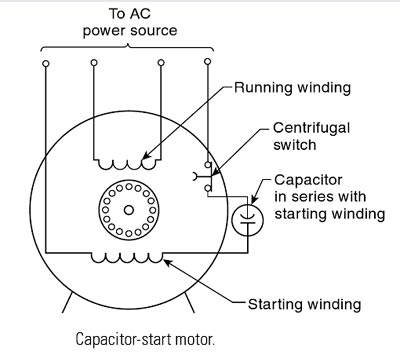

Answer.2. Starting torque Explanation:- Capacitor-Start Motors The capacitor start motor is identical to the split-phase motor in both construction and operation, except that a capacitor is installed in series with the starting winding, as shown in Fig. Also, the starting winding of the capacitor start motor is usually wound with larger wire than that used for the starting winding of the split-phase motor. The use of a capacitor in series with the starting winding causes the current in this winding to lead the voltage, whereas the current in the running winding lags the voltage by virtue of the high inductance of that winding. With this arrangement. the phase displacement between the two windings can be made to approach 90 electrical degrees so that we two-phase starting is achieved. For this reason, the starting torque of the capacitor start motor is very high, which makes it an ideal drive for the small compressor that must be started under full load. So if the low value of the capacitor is used in the motor the phase angle between the starting and running winding will be reduced and the motor can’t generate enough torque to rotate the motor.

Ques.43. The capacity of Single phase induction motor is limited by (SSC-2016)

- Pulsating Torque

- Uniform Torque

- Non-Uniform Torque

- None of these

Answer.1. Pulsating Torque Explanation:- Consider the case that the rotor of the single-phase induction motor is stationary and the stator is connected to a single-phase supply. When a single-phase supply is connected to the stator winding a pulsating or Alternating magnetic field is produced. This pulsating field builds up in one direction, falls to zero and then builds up in the opposite direction. Under this condition, the resultant torque is zero and the pulsating magnetic field cannot produce rotation in the rotor. Therefore, a single phase induction motor is not a self-starting motor. So if the rotor is ‘artificially’ started in one direction or the other, it will continue to rotate in that direction. This initial start is effected by adding a start winding, electrically a few degrees out-of-phase with the main stator winding. The field moves from the start winding to the main winding, and so the rotor receives a pulse start torque. The start winding is switched out of circuit when the rotor is up to speed. The single-phase induction motor displays similar characteristics to those of the three-phase induction motor. The pulsating torque results from the interactions of the opposite fluxes and m.m.f.’s which cross each other at twice the synchronous speed such as the interaction of the forward flux with the backward rotor m.m.f. and of the backward flux with the forward rotor m.m.f. The interaction of the forward flux with the rotor forward m.m.f. and that of the backward flux with rotor backward m.m.f. produce constant torque. Note that the pulsating torque produces no average torque but rather produces a- humming effect and makes single-phase motors noisier than polyphase motors. Losses :- The alternation in field flux would cause excessive eddy current losses in the field core and yoke. The inductances of the field and armature windings cause abnormal voltage drops. So the torque developed is lower. Single-phase ac motors are employed for low-voltage, low-power applications -fractional-kW motors. They operate on the same basic principles as the 3-phase motor, but the pulsating single-phase field produces additional losses, reducing motor torque and the pulsating torque component increases the noise level of the motor. Therefore the capacity of the single-phase induction motor is limited by its pulsating torque hence the size of single-phase motors are limited to 5-hp.

Ques.44. If the capacitor of a single phase motor is short-circuited, the motor will (SSC-2016)

- Start normally

- Not start at all

- Start with jerk

- Start and then stop

Answer.2. Not start at all Explanation:- If the capacitor of single-phase induction motor is short circuit then auxiliary winding will act as open circuit because capacitive reactance will become infinite of auxiliary winding. XC = 1/2πfC If C = 0 then Xc = ∞ So there will be no phase difference between main and auxiliary winding magnetic fields and motor starting torque will not produce. That’s why the motor will not run. When the capacitor is short-circuited high inrush current will flow in the winding which may burn the starting winding of a single-phase induction motor.

Ques.45. In which of the following voltage sources, the movement of conductors in a magnetic field is used to produce voltage? (SSC-2016)

- Thermocouple

- Zinc Copper Element

- DC generator

- Transformer

Answer.3. DC generator Explanation:-

Ques.46. Which of the following is a correct statement about a series motor? (SSC-2016)

- Its field winding consists of thicker wire and fewer turns

- It can run easily without load

- It has an almost constant speed

- It has poor torque

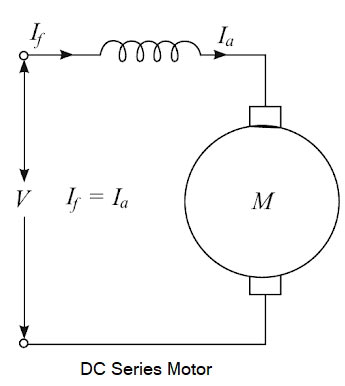

Answer.1. Its field winding consists of thicker wire and fewer turns Explanation:- In a dc series, motor and generator respectively as the field winding is connected in series with the armature, If= Ia = IL. In the case of a dc series machine, therefore, the field winding is made up of thick winding wires such that the armature current can flow through wires of the field winding without overheating. Also since the series winding carries the whole of load current, it is designed to have very low resistance (about 0.5Ω). For this reason, the series field winding has a few turns of thick wire.

Ques.47. A servo system must have ____ (SSC-2016)

- Feedback system

- Power amplifier to amplify an error

- Capacity to control position or its derivative

- All options are correct

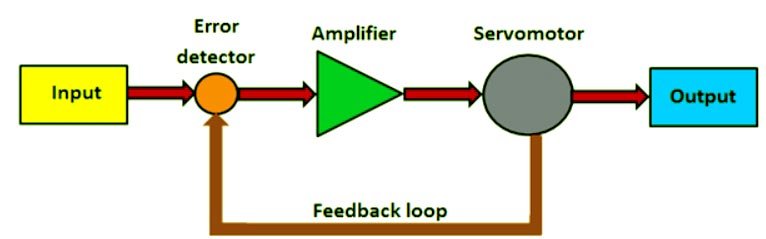

Answer.4. All options are correct Explanation:- A servo system is defined here as the drive, motor, and feedback device that allows precise control of position, velocity, or torque using feedback loops. Examples of servomotors include motors used in machine tools and automation robots. Stepper motors allow precise control of motion as well, but they are not servos because they are normally run “open loop,” without tuning and without the need for stability analysis. The basic block Diagram of Servo System is given below Amplifier:- The function of the amplifier is to amplify the servo error voltage e by some constant K, and to produce a defined output which causes the motor to move the load inertia to reduce the servo error. Feedback:- Input and feedback signals may take the form of voltages, currents, frequencies, temperature, etc., and appropriate transducers must be incorporated within the loop to enable the input and feedback terms to be added algebraically and to present the amplifier with an error voltage appropriate to its design. Precise Control:- The servo system must be supplied with position and/or velocity commands from a robot controller, which may control either single or multiple robot motors. The controller takes the position command received from a central computer and converts it to the necessary motor control signals. These signals precisely control motor position over time, thereby also controlling motor acceleration, run velocity, and deceleration.

Ques.48. As compared to a split-phase motor, a capacitor start motor has ________. (SSC-2016)

- Higher starting torque

- Lower starting torque

- Higher running torque

- None of these

Answer.1. Higher starting torque Explanation:- Capacitor-Start Motors The capacitor start motor is identical to the split-phase motor in both construction and operation, except that a capacitor is installed in series with the starting winding, as shown in Fig. Also, the starting winding of the capacitor start motor is usually wound with larger wire than that used for the starting winding of the split-phase motor. The use of a capacitor in series with the starting winding causes the current in this winding to lead the voltage, whereas the current in the running winding lags the voltage by virtue of the high inductance of that winding. With this arrangement. the phase displacement between the two windings can be made to approach 90 electrical degrees so that we two-phase starting is achieved. For this reason, the starting torque of the capacitor start motor is very high, which makes it an ideal drive for the small compressor that must be started under full load.

Ques.49. Locked rotor current of a shaded pole motor is (SSC-2015)

- Less than the full load current

- Equal to full load current

- Several times the full load current

- Slightly more than the full load current

Answer.4. Slightly more than the full load current Explanation:- The shaded-pole motor is rugged, inexpensive, small in size, and requires little maintenance. Its stalled locked-rotor current is only slightly higher than its normal rated current so that it can even remain stalled for short periods without harm.

Ques.50. The purpose of starting winding in a single-phase induction motor is to? (SSC-2015)

- Produce rotating flux in conjunction with the main winding

- The limit temperature rise of the machine

- Reduces Losses

- Increase losses

Answer.1. Produce rotating flux in conjunction with the main winding Explanation:- In single-phase motors, there is only one main winding and a single-phase supply. So there is no RMF (rotating magnetic flux) generated inside the stator of such machines. So such machines are not inherently self-starting. The auxiliary winding or starting winding is connected to the ac mains via a capacitor in order to generate a two-phase supply, which can generate RMF when the coils are spatially placed at 90° with respect to the main winding. This RMF is responsible for the operation of single-phase induction motors. Adding the capacitor makes the motor self-starting.