Ques.71. Name the equipment which runs an alternator

- Prime Mover✓

- Generator

- Motor

- Fan

All generators, large and small, ac and dc, require a source of mechanical power to turn their rotors. This source of mechanical energy is called a prime mover. When a prime mover drives the synchronous machine, it functions as an alternator concerting the mechanical energy of the prime mover into electrical energy.

Prime movers are divided into two classes for generators-high-speed and low-speed. Steam and gas turbines are high-speed prime movers, while internal-combustion engines, water, and electric motors are considered low-speed prime movers. The type of prime mover plays an important part in the design of alternators since the speed at which the rotor is turned determines certain characteristics of alternator construction and operation.

Ques.72. Electric strength in a cable is more on

- Layer on the conductor✓

- Outside of the conductor

- The outer side of the armoring

- None of these

The electric strength of insulation material is the ability to withstand an applied voltage without a breakdown. The voltage between the conductors at which the surrounding air is ionized is called the breakdown voltage or disruptive voltage. Break down voltage depends on atmospheric conditions and also surface conditions of the conductor. Electric strength in a cable is more on layer on the conductor. or Electric strength is the maximum voltage that an insulating material can take, after which it loses its insulating properties. The higher the electric strength, the more useful is the material as an insulator. Hence the cable must be designed so that the electric field strength, or maximum electric stress, at the surface of the conductor, does not exceed that required to break down the insulation. When the potential is applied to the conductors, a potential gradient is developed in the air. This potential gradient is maximum around the surface of the conductors. Due to the potential gradient, the free electrons will start moving with a certain velocity which depends on the field strength. The greater is the applied voltage, the higher is the potential gradient and the velocity acquired by the free electrons. If the voltage is higher than the electric strength, an electric breakdown occurs. No matter which mechanism initiates the breakdown, the result is a sudden discharge of the voltage through the insulation. In cable insulation, such an event inevitably leads to a complete failure and an outage of the power line. The cable insulation must be designed such that it can withstand all expected voltages during the lifetime of the cable. The electric strength is a material property given in kV/mm. There are no fixed values for solid insulation materials, even if cables with electric strength values can be found in many textbooks and journal articles. The electric strength of a given material is depending on a number of parameters under which the electric strength has been measured. Sometimes, the concept of the “intrinsic dielectric strength” of a material is used. The electrical stress at the surface of a conductor is given by ${E_r} = \dfrac{{{V_{LN}}}}{{r\ln \left( {\dfrac{R}{r}} \right)}}$ VLN = The voltage between the inner cylinder (the conductor) and the outer cylinder (the Earth surface) r = radius of the conductor R = height of the conductor above the ground When we want a low electric field strength at the conductor surface, we have to choose thick conductors. By increasing the diameter of the conductor, the distance between the equipotential lines increases, and the electric field strength at the surface of the conductor, decreases. However, thick conductors are heavy and, besides the fact that more material is needed to manufacture them, they require more rigid tower structures which makes this solution an expensive one. A much better solution is to divide the conductor into bundles. Instead of one conductor per phase, multiple conductors are used per phase.

Ques.73. In places where acids and alkalies are present, the type of wiring used is

- PVC✓

- TRS

- VIR

- Weather Proof

In the field of insulated cables, PVC cables have occupied an important place and in fact, these are most popularly used in homes for domestic wiring. Various types of PVC cables are available, e.g., cables for control, signaling, instrumentation, rural electrification, house wiring, communication as well as for use in wires, automobiles, T.V. electric welding etc. These cables are suitable where the wire temperature during use does not exceed 70°C. Polyvinyl chloride (PVC) cables are used for the low and medium voltage distribution system. They are usually of two grades viz., 250/440 volts grade cable and 640 ⁄ 1100 volts grade cable. The conductors used in these cables are also of stranded aluminum or copper wires which are separately insulated with PVC insulation. Wiring with PVC sheathed cables is installed directly in underexposed conditions of sun and rain or in damp places. This system of wiring is suitable in situations where acids and alkalis are likely to be present. Where attack from white ants (termite) is prevalent, anti-termite treatment should be given. In cases where there are chances of any damage to the wirings, they should be covered with sheet metal protective covering. The base of the covering is made flush with plaster or brickwork. PVC cables are more flexible, non-draining, and have the following properties.PVC wiring

Advantages of CTS or TRS wiring system

Disadvantages of CTS or TRS wiring system

Ques.74. Replacement of wiring is not easy in which type of wiring

- Conduit System

- Lead sheathed

- Concealed wiring✓

- Cleat System

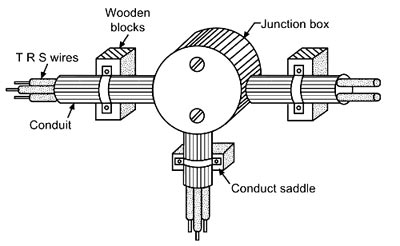

In conduit wiring, wires are carried through steel or iron pipes giving good protection from mechanical injury or fire risks. This system is the best and most desirable system of wiring for workshops and public buildings. Surface conduit wiring: in this method conduits are mounted or supported on the walls with the help of pipe books or saddles. In damp situations, the conduits are spaced apart from the wall by means of wooden blocks. Concealed conduit wiring: in this method, the conduits are buried under the wall at the time of plastering. This is also called recessed conduit wiring. The beauty of the premises is maintained due to conduit wiring. It is durable and has a long life lt protects the wires from mechanical shocks and fire hazards. Proper earthing of conduits makes the method electrical shock-proof. It requires very less maintenance. The repairs are very difficult in the case of concealed conduit wiring. This method is most costly and erection requires highly skilled labor. These are a few disadvantages of the conduit type of wiring. In concealed conduit wiring, keeping conduit at earth potential is necessary.Conduit wiring system

Advantages of Conduit Wiring Systems

Disadvantages of Conduit Wiring Systems

Ques.75. ACSR conductor means

- All conductor Steel Reinforced

- Aluminum conductor steel reinforced✓

- Aluminum conduit steel reinforced

- All conduit steel reinforced

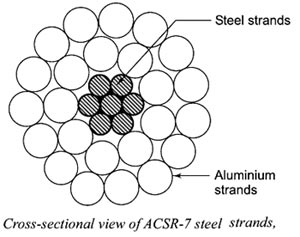

Aluminum conductor steel-reinforced cable (ACSR) is a type of high-capacity, high-strength stranded conductor typically used in overhead power lines. An ACSR conductor has a central core of galvanized steel wire covered with successive layers of aluminum strands, which are electrically in parallel. Because of galvanized steel wire, the tensile strength of the conductor is increased, so that the sag is reduced. It reduces the tower height and is useful for increasing the span length. Another advantage of the ACSR is that the diameter of the conductor may be increased so that the effect of the corona is less. The cross-sectional view of such a conductor is shown in Fig..When compared with the equivalent copper conductor. the breaking strength of ACSR is high, whereas its weight is less. For large span. the number of transmission line supports required will be reduced. Therefore, the cost of support, foundation, insulators, erection, and at the same time, the cost of maintenance is reduced. The ACSR conductors have the following advantaged

Ques.76. The value of supply voltage for 500 W, 5-ohm load is

- 100 V

- 500 V

- 50 V✓

- 10 V

Power is given as P = V2/R 500 = V2/5 V2 = 2500 V = 50 V

Ques.77. The most important factor with respect to lighting quality is

- Color

- Glare✓

- Illumination

- Uniform Lighting

Glare is the most important factor with respect to lighting quality, it is caused by luminance in the visual field that is too bright. It can cause discomfort and reduced productivity and is highly subjective in that some people can be more sensitive to it than others. A bright object alone does not necessarily cause glare, but a bright object in front of a dark background will usually cause it. Contrast is the relationship between the luminance of an object and its background. Although a task generally becomes easier with increased contrast, too much causes glare and makes a task much more difficult. Glare can be reduced by not exceeding suggested light levels and by using lighting equipment designed to reduce glare. Louvers and lens are commonly used to block direct viewing of a light source. The use of indirect lighting, or uplighting, is an excellent means of preventing glare by uniformly lighting a ceiling, or creating a ‘wash” of light on a wall.

Ques.78. In ACSR conductors, the insulation between aluminum and steel conductors is

- Varnish

- Bitumen

- Ceramic

- No insulation is required✓

One of the most common conductor types is an aluminum conductor, steel-reinforced (ACSR), which consists of layers of aluminum strands surrounding a central core of steel strands. Stranded conductors are easier to manufacture since larger conductor sizes can be obtained by simply adding successive layers of strands. Stranded conductors are also easier to handle and more flexible than solid conductors, especially in larger sizes. The use of steel strands gives ACSR conductors a high strength-to-weight ratio. For purposes of heat dissipation, overhead transmission-line conductors are bare (no insulating cover). In insulation cover, the heat dissipation capacity is limited as compared to when it was naked and hence its current carrying capacity is very much reduced and now depends on allowable temperature rise. Also, the insulation will raise the initial cost of an overhead transmission line.

Ques.79. Which one of the given fuses is bigger?

- DC✓

- AC

- DC or AC

- Both have same fuse size

DC Fuses The main difference between the DC Fuses and AC Fuses is the size of the fuse. In a DC circuit, when the current exceeds the limit, the metallic wire in the fuse melts and disconnects the rest of the circuit from the power supply. When the fuse blows due to over-current, an arc can form, re-energizing faulty load. Since DC is the constant value and is always above 0V, there is a chance of an electric arc between the melted wires, which will be difficult to avoid and turn off. Hence, usually, the electrodes of the DC Fuses are placed at a larger distance when compared to the AC Fuses. This will minimize the chance of arc and since the distance between the electrodes is increased, the size of the DC Fuses is comparatively large. AC Fuses We know that AC current (and voltage) oscillates 50 or 60 times per second and in this, the amplitude of the signal varies from minimum to maximum. At one point of this oscillations, the AC Voltage touches the 0V and hence the arc between the melted electrodes can be easily terminated. As a result, the size of the AC Fuses can be much smaller when compared to the size of DC Fuses.

Ques.80. What is the function of choke in a fluorescent lamp?

- Starting Purpose

- Produce High voltage at starting✓

- Improve power factor

- Minimize the power consumption

There are mainly two functions of the choke coil Choke must provide a suitable striking (ignition) voltage across the bulb at starting such that an electric arc can sustain between the electrodes afterward. Secondly, the ballast is responsible for limiting the current flow across the lamp during its normal operation of it. As the initial impedance is high, the striking voltage required to ignite the arc would also be higher than the normal operating voltage (around 300% higher) of a fluorescent lamp. Immediately after the lamp is struck, the impedance drops to its minimum value, representing negative resistance characteristics that need some form of current limiting to prevent lamp destruction from excessive current.

Limit the current

Produces High voltage Across Tubelight