Thermal overload relays are used to protect the motor against overcurrent due to

Right Answer is:

Heavy loads

SOLUTION

The thermal protection switch protects against overload. Thermal breakers are used where overloads can be tolerated for an extended time, such as in commercial wiring and in the protection of motors, transformers, and tungsten lamp loads. The long temperature-dependent delay means the thermal breakers are not applicable to electronic systems and power conversion equipment protection,

Thermal overload relay or switches can be divided into two types:-

- Melting type

- Bimetallic type

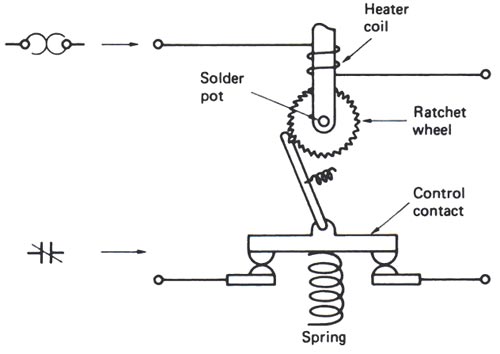

Melting overload Relay or Solder Melting Pot

To create this type of overload, a bra shaft is placed inside a brass tube. In these overload relays (also referred to as “solder pot relays”), the motor current passes through a small heater winding. The heating element is connected in series with the motor. The current that flows through the motor windings also flows through the heating element. The heating element is calibrated to produce a certain amount of heat when a predetermined amount of current flows through it. As long as the current flowing through it does not exceed a certain amount, there is not enough heat produced to melt the solder.

Under overload conditions, an excessive amount of current will flow through the heater causing excessive heat the heat causes a special solder to melt, allowing a ratchet wheel to spin free, opening the contacts. When this occurs, the relay is said to ” trip.” To obtain appropriate tripping current for motors of different sizes, of different full-load currents, a range of thermal units (heaters) is available. The heater coil and solder pot are combined in a one-piece, no-tamperable unit. The heat transfer characteristic and the accuracy of the unit cannot be accidentally changed, as is possible when the heater is a separate component. Melting alloy thermal overload relays are “hand reset,” thus after they trip they must be reset by a deliberate hand operation. A reset button is usually mounted on the cover of enclosed starters. Thermal units are rated in amperes and are selected on the basis of motor full-load current.

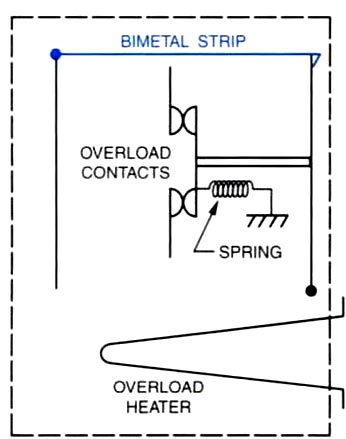

Bimetal type Overload Relay

The bimetal type of overload operates very similarly to the solder-melting type except a bimetal strip is used to cause the contacts to open. In this unit, the bimetal strip is used to mechanically hold the spring-loaded contacts closed. If the current flow through the heater becomes excessive the bimetal strip will warp and permit the spring to open the contacts. After the overload unit has tripped the bimetal strip must be allowed some time to cool before it can be reset. This type of unit has an advantage over the solder-melting type in that it, be adjusted for manual reset or automatic. The solder-melting type of overload must be manually reset.