V/f is maintained constant in the following case of speed control of induction motor

Right Answer is:

Below the base speed with frequency control

SOLUTION

V/f is maintained constant for below the base speed with frequency control in case of speed control of induction motor.

An induction motor on a normal supply operates with a rotating field set up by three-phase currents in the stator winding. The magnitude of the field is controlled broadly by the voltage impressed upon the winding by the supply. This is because the resistance of the winding results in only a small voltage drop, even at full-load current, and therefore in the steady-state the supply voltage must be balanced by the e.m.f. induced by the rotating field. This e.m.f. depends on the product of three factors:

- The total flux per pole (which is usually determined by the machine designer).

- The total number of turns per phase of the stator winding.

- The rate of field rotation or frequency.

Synchronous speed, therefore, the motor speed can be controlled by varying supply frequency. The voltage induced in the stator is proportional to the product of supply frequency and air-gap flux. If stator drop is neglected, the terminal voltage can be considered proportional to the product of frequency and flux.

V = φF

and

φ = V/F

And also the torque of an induction motor is directly proportional to the flux

T ∝ φ ∝ V/F

Hence for the same design parameters [φ remaining the same] and ratio V/F, the torque of the motor, T, will remain constant. Since both V and f, are functions of the supply system, a variation in V and f can alter the performance and the speed-torque characteristics of a motor as required, at constant torque.

Base Speed

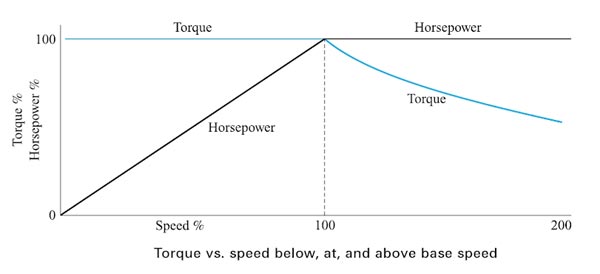

Base speed,” is defined as the speed at which the motor will first produce its maximum designed power output, and “maximum speed,” the fastest the motor can spin while producing that same amount of power (available torque falls off as speed increases past “base speed.”)

Operation above base speed

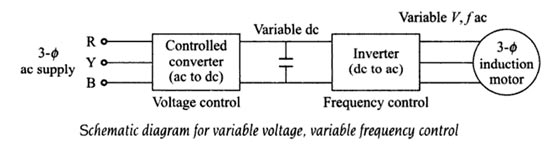

First, operation above base speed is easily achieved by increasing the output frequency above the normal mains frequency since the rise in the applied voltage is not permitted beyond the rated voltage, and which has already been attained by reaching the rated speed. The speed beyond the rate is therefore obtained by raising the supply frequency alone and maintaining the voltage at constant as it rated value.

Since V is constant above base speed, the flux will fall as the frequency is increased after the output voltage limit is reached. The machine flux falls in direct proportion to the actual V/f ratio. Although this greatly reduces the core losses, the ability of the machine to produce torque is impaired and less mechanical load is needed to draw full-load current from the inverter. The drive is said to have a constant power characteristic above base speed. Many applications not requiring full torque at high speeds can make use of this extended speed range.

Operation below base speed

Each AC induction motor is designed to run at a particular RPM, called base speed. When power is applied, the motor accelerates from 0 RPM. As it does, the torque remains constant and the horsepower increases until the base speed is reached, . Above base speed, the torque falls off while the horsepower remains constant.

Below the base speed (V/F ratio is maintained constant, except at low frequencies where (V/f ) ratio is increased to keep maximum torque constant.

By maintaining a constant ratio of voltage to speed, we can maintain a constant air gap flux. Because torque is proportional to air gap flux, hence by constant V/f ratio, the torque can be made independent of speed in an AC motor. Hence we can achieve constant torque down to very low speeds.

Example

One example is a paper winder. When it begins to wind, the empty core is light and does not require much torque to turn. Therefore, it can be turned above base speed at reduced torque. As the roll is being wound and becomes heavier, the torque required to turn it becomes greater. Therefore, it is necessary for the drive to slow the speed and eventually run below the base speed so that torque is increased to handle the load. Eventually, the roll is heavy and requires the motor to provide maximum torque.