Synchronous Motor Working Principle

- Electric Motor is an electromechanical device which transforms electric energy into mechanical energy.

- According to their type of connection, electric motors are generally classified into the two types i.e single phase motor and three phase motor.

- A synchronous motor is a 3 phase motor and it closely resembles 3 phase alternator.

- 3 phase synchronous motor and 3 phase induction motor are most widely used AC motor.

- A synchronous motor is also called as doubly excited motor.

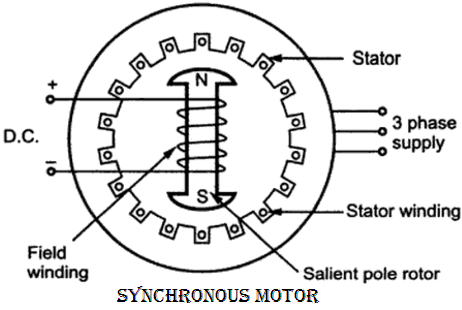

The synchronous motor consist of the two parts:

Stator: Stator is the armature winding. It consists of three phase star or delta connected winding and excited by 3 phase A.C supply.

Rotor: Rotor is a field winding. The field winding is excited by the separate D.C supply through the slip ring.

The construction of Rotor can be salient pole (projected pole) and non-salient pole (cylindrical pole) type.

Principle Of Working Of Synchronous Motor

- Synchronous motor work on the principle of magnetic locking.

- When two unlike strong unlike magnets poles are brought together, there exists a tremendous force of extraction between those two poles. In such condition, the two magnets are said to be magnetically locked.

- If now one of the two magnets is rotated, the other magnets also rotate in the same direction with the same speed due to the strong force of attraction.

- This phenomenon is called as magnetic locking

For magnetic locking condition, there must be two unlike poles and magnetic axes of this two poles must be brought very nearer to each other.

- Consider a synchronous motor whose stator is wound for 2 poles.

- The stator winding is excited with 3 phase A.C supply and rotor winding with D.C supply respectively. Thus two magnetic fields are produced in the synchronous motor.

- When the 3 phase winding is supplied by 3 phase A.C supply than the rotating magnetic field or flux is produced.

- This magnetic field or flux rotates in a space at a speed called synchronous speed.

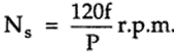

- The rotating magnetic field or rotating flux has fixed relationship between, the number of poles, the frequency of a.c supply and the speed of rotation.

- The rotating magnetic field creates an effect which is similar to the physical rotation of magnets in space with a synchronous speed.

- So for rotating magnetic field

Where f = supply frequency

P = Number of poles

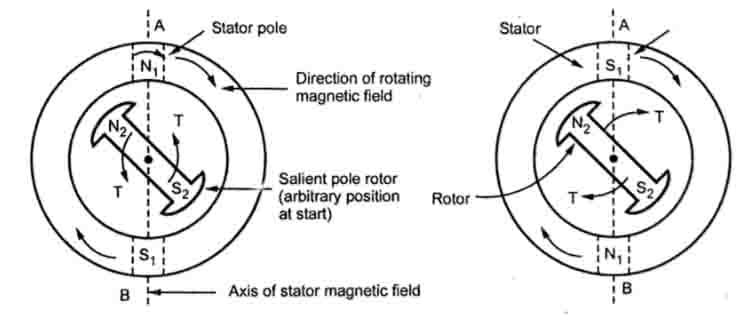

- Suppose the stator poles are N1 and S1 which are rotating at a speed of Ns and the direction of rotation be clockwise.

- When the field winding on a rotor is excited by the D.C source, it produces the two stationary poles i.e N2 and S2.

- To establish the magnetic locking between the stator and rotor poles the, unlike poles N1 and S2 or N2 and S1 should be brought near to each other.

- As stator poles are rotating and due to magnetic locking the rotor poles will rotate in the same direction of rotating magnetic field as that of stator poles with the same speed Ns.

- Hence synchronous motor rotates at only one speed that is synchronous speed.

- The synchronous speed depends on the frequency therefore for constant supply frequency synchronous motor speed will be constant irrespective of the load changed.

Features of Synchronous Motor

- It runs either at synchronous speed or not at all. That is while running it maintains a constant speed. The speed is independent of load.

- It is not inherently self-starting. It has to be run at synchronous speed by some means before it can be synchronized to supply.

- It can be operated under the wide range of power factors both lagging and leading.

- It will stall if, while running, counter torque is increased beyond the maximum torque that machine can develop.

- The speed of the synchronous motor can be controlled by inverter units.

Application of Synchronous Motor.

Synchronous motor finds various application for following services:

- Power Factor correction

- Voltage Regulation

- Constant speed, Constant load drives

Power Factor Correction

- Over excited synchronous motor having leading power factor are widely used for improving power factor for those power system which employs a large number of an induction motor.

- Under excited synchronous motor having lagging power factor found application in fluorescent light welding etc.

Voltage Regulation

- The voltage at the long transmission lines varies greatly when the large inductive load is present.

- When line voltage decreases due to inductive load, motor excitation is increased thereby raising its power factor which compensates for the line drop.

- If line voltage rises due to line capacitive effect, motor excitation is decreased thereby making its power factor lagging which helps to maintain the line voltage to its normal value.

Constant Speed Application

- Because of their high efficiency and high-speed synchronous motor are well suited for loads where constant speed is required such as a centrifugal pump, blowers, line shaft, paper mills etc.