Which of the following generators are used in arc welding?

Right Answer is:

Differential compound generators

SOLUTION

Arc welding is the widely used method of joining metal parts. Here the source of heat is an electric arc. Arc welding is a group of welding processes wherein the heating is produced with an electric arc or arcs, mostly without the application of pressure and with or without the use of fillet metal, depending upon the base plate thickness.

ARC Welding Principle

In arc welding, the ARC is generated between the positive pole of D.C. (direct current) called the anode and the negative pole of D.C. called the cathode. When these two poles are brought together, and separated for a small distance (1.5 to 3 mm) such that the current continues to flow through a path of ionized particles, called plasma, an electric arc is formed. Since the resistance of this ionized gas column is high, so more ions will flow from the anode to the cathode. Heat is generated as the ions strike the cathode.

A.C. or D.C. Machines in ARC Welding

Depending upon the application, A.C. or D.C. machines are used in arc welding, but in some cases, either of them can be used. D.C. supply is usually obtained from generators driven by an electric motor or if no electricity is available then the diesel engine can be used. D.C. welding is mostly used for heavy work and at sites where electricity is not available.

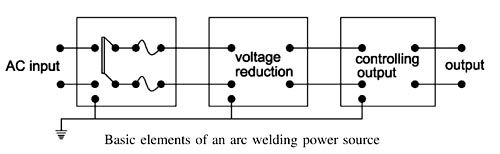

Arc welding requires a power source that can deliver electrical power at low voltage and high current such that it can establish and sustain an arc plasma column between the welding electrode and the workpiece. The line voltage in the mains supply is too high to be used directly in arc welding. Therefore either a transformer, solid-state inverter/rectifier or a motor-generator set is used to obtain the required open-circuit voltage necessary for arc welding. It is generally in the range of 20-80 V. At the same time, the same power source should be capable of delivering a high current typically ranging from 50 to 1500 A. This welding power source can have the output of alternating current (AC) or direct current (DC). These power sources have volt-ampere characteristics typically of constant current (CC) or constant potential (CP) type. The output may also have a pulsing mode. A schematic of the basic elements of an arc welding power source is shown in Fig.

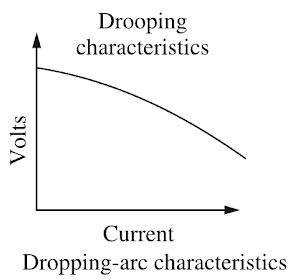

An arc behaves in a totally different manner from a norms resistance. As the current is increased the potential drop across the arc, instead of increasing as with an ohmic resistance, decreases up to a current of the order of 50-70 A, and then becomes approximately constant. This is because with increasing current arc increases in size, allowing a larger area for curve flow, and also increases in temperature becoming thereby more conducting.

The generator used for welding purposes should have high current and low voltage which can be obtained by the differential compound generator. Differentially compounded DC generator has drooping characteristics that mean if load current increases the net flux will decreases(i.e shunt field and series fields in opposition will increases)due to demagnetization effect hence the Induced EMF and terminal voltage decreases.