Heating And Welding MCQ Questions & Answers with Explanation

Ques.1. In arc welding, the temperature of the arc is of the order of

- 100° C

- 1000° C

- 3500° C

- 35000° C

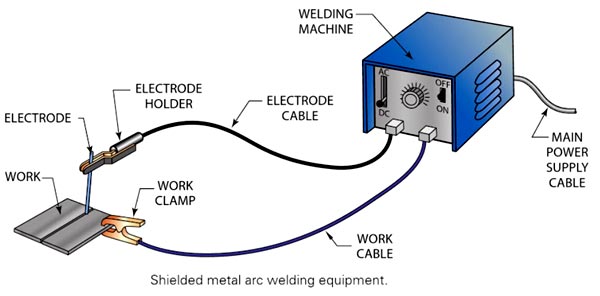

Answer.3. 3500°C Explanation:- Welding is the process of joining metallic parts by bringing them into intimate proximity and heating the places of contact to the state of fusion or plasticity. This leads to the interpenetration of atoms of the metals in the weld zone and a strong inseparable joint is formed after the metals have cooled. Arc Welding Arc welding is used to join metals. An electric arc is created between an electrode and the components being joined in order to melt the components in the joint area. A filler material is fed into the joint at the same time. Arc-welding processes include shielded metal arc welding, metal inert gas welding, tungsten inert gas welding, plasma arc welding, and submerged arc welding. In this process, an electric arc is produced bat bringing two conductors (electrode and metal piece) connected to a suitable source of electric current, momentarily in contact and then separated by a small gap, arc blows due to the ionization and gives intense heat. The heat so developed is utilized to melt the part of the workpiece and filler metal and thus forms the weld. For arc welding, the temperature of the arc should be 3,500°C. At this temperature, mechanical pressure for melting is not required. Both AC and DC can be used in arc welding. Usually, 70-100 V on AC supply and 50-100 V on the DC supply system is sufficient to strike the arc in the air gap between the electrodes. Once the arc is struck, 20-30 V is only required to maintain it. Note:- For More information about Welding equipment check out How to Wire a 50-Amp Plug for Welder?

Ques.2. The arc in the welding has

- Linear resistance characteristics

- Positive resistance characteristics

- Negative resistance characteristics

- Highly inductive characteristics

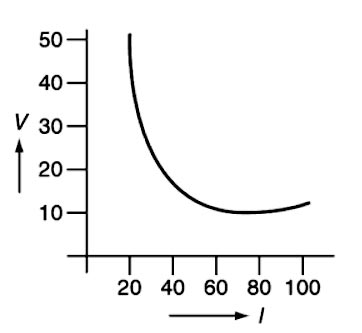

Answer.3. Negative resistance characteristics Explanation:- In an ARC WELDING when the supply is given across the conductors separated by some distance apart, the air gap present between the two conductors gets ionized, as the arc welding is in progress, the ionization of the arc path and its surrounding area increases. As the current is increased, the temperature increases, and therefore the conductivity increases. More ions are formed, so the arc resistance is towered and the arc voltage is decreased. We say that the arc has a negative resistance characteristic because the voltage drops with higher currents. Thus, current increases with the decrease in voltage of the arc. This V-I characteristic of an arc is shown in fig. It is also known as the negative resistance characteristics of an arc. Thus, it will be seen that this decrease in resistance with an increase in current does not remain the arc steadily. This difficulty can be avoided, with the supply, it should fall rapidly with the increase in the current so that any further increase in the current is restricted.

Ques.3. Arc can be produced by

- AC current only

- DC current only

- Either AC or DC current

- All of the above

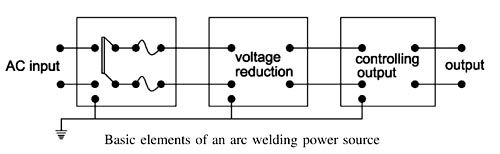

Answer.3. Either AC or DC current Explanation:- The arc can be produced by either AC or DC current. The regular electric power supply (hydel power or thermoelectric) uses high voltage and low current. It cannot be used directly for welding purposes without a welding machine, which is specially designed and constructed to change the high voltage low ampere current into a safe low voltage (which is usually between 50 and 100 volts) and a heavy current supply upto 600 A The transformer does not have any moving parts and as a result, operates with less maintenance cost and also has higher efficiency. The power used is also less expensive and there is practically no noise in the operation of the welding transformer. In AC welding, normally only transformers are used. Arc welding equipment are of two types:- AC machine An AC generator set comprises an AC generator (alternator) to produce AC power for welding and a prime mover to run the generator. The prime mover may be either an AC motor or more often a petrol or diesel engine. AC generator can deliver current at a normal frequency (50 Hz) or high frequency. The electric motor-driven generator sets are those which employ a motor to move at a normal frequency (50 Hz) and drive a generator that produces AC power at some higher frequency for special welding applications. Engine-driven AC generator sets are used for welding in remote situations where no electric power is available. DC arc welding machines: These are further divided as (i) DC generator set, motor-driven or engine driven and (ii) Transformer rectifier set. One big advantage of a DC welding set is that either straight or reverse polarity can be used. DC generator sets consist of a DC generator powered by either an AC electric motor or an engine (petrol or diesel). The generator set provides DC power in either straight polarity or reverses polarity using a polarity switch given on the machine. The generator supplies voltage usually between 15 and 45 volts across the arc and the open-circuit voltage is between 45 and 70 volts and the current supply is upto 600 amperes. DC rectifier sets consist of a transformer to lower down the input AC voltage and a silicon or selenium rectifier to convert AC into DC. The machine has no moving part except a moving fan to cool the transformer. The DC rectifier set gives either straight or reverses polarity. The machine is quiet in operation with low maintenance. AC/DC arc welding machines: These are basically AC/DC transformers—rectifier type welding machines that give either AC or DC power for welding (only one type of power at a time). Rectifier units are designed to provide a choice of low voltages for MIG welding or submerged arc welding and a high open-circuit voltage with drooping voltage characteristics (constant current type) for TIG welding, and manual arc welding. The open-circuit voltage may be up to 75 volts and arc voltage 25 to 50 volts with current ratings from 200 to 1000 amperes.

Ques.4. The resistance of the arc

- Decrease with an increase of the current

- Increases with increases of the current

- Does not depends on current

- None of the above

Answer.1. Decrease with an increase of the current Explanation:- In an ARC WELDING when the supply is given across the conductors separated by some distance apart, the air gap present between the two conductors gets ionized, as the arc welding is in progress, the ionization of the arc path and its surrounding area increases. As the current is increased, the temperature increases, and therefore the conductivity increases. More ions are formed, so the arc resistance is towered and the arc voltage is decreased. We say that the arc has a negative resistance characteristic because the voltage drops with higher currents. The resistance of the arc may be increased by:

Ques.5. In arc welding, the voltage on A.C supply system is in the range

- 1000-1200 V

- 400-500 V

- 200-250 V

- 70-100V

Answer.4. 70-100V Explanation:- For electric arc welding, both an alternating current (A.C.) and direct current (D.C.) are used. For A.C. arc welding normally a step-down transformer is utilized which receives current from the supply mains at 220 volts (in case of single-phase supply) and 400 to 440 volts (in case of three-phase supply) and transforms it to the normally open circuit welding voltage (80-100 volts). In the case of A.C. arc welding, we reduce the incoming voltage to 80-100 volts. This voltage is actually needed only for striking the arc but for maintaining the same, we require a still voltage of about 35 to 40 volts. The current regulators accomplish the desired voltage by adjusting the flow of the current. There is no fixed polarity at the terminals in the case of A.C. welding. So an arc is created by low voltage, high current supply. In A.C. supply, it does not matter whether the work or the electrode is positive, or in other words, there is no polarity.

Ques.6. In arc welding by DC supply, the voltage required is

- 10 to 20 V

- 50 to 60 V

- 100 to 120 V

- 200 to 250 V

Answer.2. 50-60V Explanation:- In the D.C arc welding process, open circuit voltage is 40-60 volts, and the arc voltage is 18-30 volts. The current for manual arc welding usually ranges from 35 to 500 ampere and for the automatic operation it is from 75 to 600 ampere. The actual amount of current required depends upon the thickness of the job.

Ques.7. In arc welding, once the arc is struck, the voltage required to maintain the arc will be

- 20-30 V

- 100-120 V

- 200-220 V

- 500-1000 V

Answer.1. 20-30V Explanation:- The voltage required to strike the arc is 40-80 volts but for maintaining the same, we require a still voltage of about 20 to 30 volts.

Ques.8. A DC generator used for A.C welding should have

- Rising characteristics

- Dropping Characteristics

- Straight characteristics

- All of the above

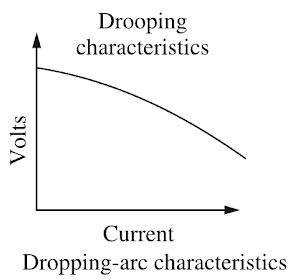

Answer.2. Dropping Characteristics Explanation:- Depending upon the application, A.C. or D.C. machines are used in arc welding, but in some cases, either of them can be used. D.C. supply is usually obtained from generators driven by an electric motor or if no electricity is available then the diesel engine can be used. D.C. welding is mostly used for heavy work and at sites where electricity is not available. Arc welding requires a power source that can deliver electrical power at low voltage and high current such that it can establish and sustain an arc plasma column between the welding electrode and the workpiece. The line voltage in the mains supply is too high to be used directly in arc welding. Therefore either a transformer, solid-state inverter/rectifier or a motor-generator set is used to obtain the required open-circuit voltage necessary for arc welding. It is generally in the range of 20-80 V. At the same time, the same power source should be capable of delivering high current typically ranging from 50 to 1500 A. This welding power source can have the output of alternating current (AC) or direct current (DC). These power sources have volt-ampere characteristics typically of constant current (CC) or constant potential (CP) type. The output may also have a pulsing mode. A schematic of the basic elements of an arc welding power source is shown in Fig. An arc behaves in a totally different manner from a norms resistance. As the current is increased the potential drop across the arc, instead of increasing as with an ohmic resistance, decreases up to a current of the order of 50-70 A, and then becomes approximately constant. This is because with increasing current arc increases in size, allowing a larger area for curve flow, and also increases in temperature becoming thereby more conducting. The generator used for welding purposes should have high current and low voltage which can be obtained by the differential compound generator. Differentially compounded DC generator has drooping characteristics that mean if load current increases the net flux will decreases(i.e shunt field and series fields in opposition will increases)due to demagnetization effect hence the Induced EMF and terminal voltage decreases.

Ques.9. The Polarity of A.C welding sets is

- Positive

- Negative

- No polarity

- Infinite

Answer.3. No polarity Explanation:- Polarity in Arc Welding: There is no polarity in A.C. arc welding due to the reversal of the current, or the heat generated al each pole is the same, and therefore, changing over the connections of the electrode and job do not have any effect on the performance of the welding

Ques.10. As the thickness of the part to be welded increases, which of the following parameter for ac welding should also increase?

- Voltage

- Current

- Frequency

- All of the above

Answer.2. Current Explanation:- The current within the usable range is selected according to the electrode size, type of metal transfer, and base metal thickness. When the current is too low, the molten metal fails to wet the joint surface and causes a lack of fusion. When the current is too high, it gives rise to spatter, porosity, and poor weld bead profile. Every electrode has a certain current range within which it operates satisfactorily. On a light job where overheating must be avoided, current on the lower side is used. For heavy work where maximum heat for adequate fusion is necessary, current at the top of the range is used. Current in the middle of the range is used for normal work. Welding current increases with electrode size. For a given electrode size, the current increases with coating thickness, because as the coating thickness increases, a higher current is required to melt it.