LATEST POSTS

Welcome to ElectricalExams.Co, this is the place for you if you want to learn the Basics of Engineering with Focus on Electrical and Electronics Engineering.

We have a large collection of Multiple Choice Questions (MCQs) to help you refresh what you have learned in the school and will prepare you to the Engineering world in the Future.

Majority of the MCQs have been categorize for ease of learning and the questions came from actual Electrical and Electronic Board Exams across the Globe. It will hep you test your knowledge from Basic Mathematics to Basic Engineering lectures that’s is why we have provided lectures from all around the world.

To test your Engineering Knowledge we have collection of MCQs for Power Electronics, Power Systems, Transformers, Electrical Earthing, Electrical Wiring, Earth Resistance, Voltage and current Sources, Electric Drives, Synchronous Motor, Single Phase Induction Motor and More solve MCQs

We have solve MCQ’s for Electrical Engineering, SSC JE Topwise Papers, SCC JE 2009-2017, SCC JE 2018, SCC JE2019, UPPCL JE, DMRC JE

For the Basic of Electrical Engineering you can check our articles on Fundamentals of Electrical Engineering, Resistance temperature coefficients, Concept of Resistance and Ohm’s Law, Fundamental Quantities and Units, Resistors in Series, Parallel, Series Parallel

For Electrical machines we have basic of learnings for Transformers, DC Machines and Synchronous Machines.

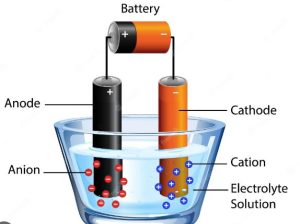

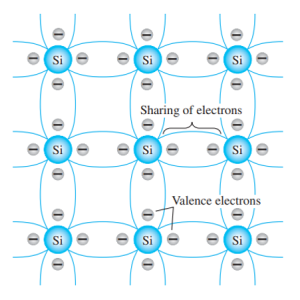

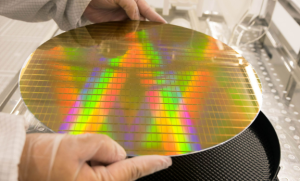

For Electronic Engineering, to learn more, you can check our Electronic Devices lectures as well.

We have included on our learnings the People who have significant contributions to all Engineering Fields in Biography Sections.

Fundamental of Electrical Engineering | Concept Of Resistance and Ohm’s Law

Read More

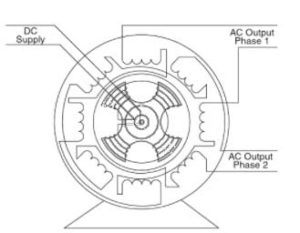

Working Principle Of An Alternator

Read More

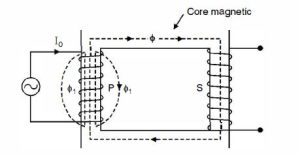

Ideal Transformer | Characteristics of Ideal Transformer

Read More

Fundamental Of Electrical Engineering

Read More

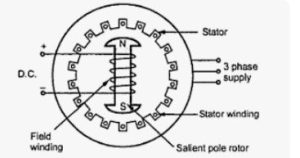

Working principle of synchronous motor

Read More

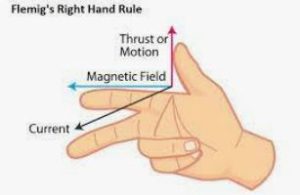

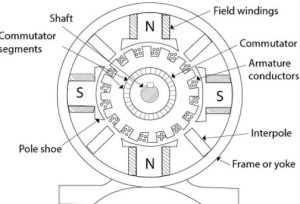

Working Principle of DC Motor

Read More

Leon Charles Thevenin – Biography, Contributions, Inventions

Read More

Georg Simon Ohm – Biography, Contributions, Inventions

Read More

Gustav Kirchhoff Biography, Contributions, Inventions

Read More