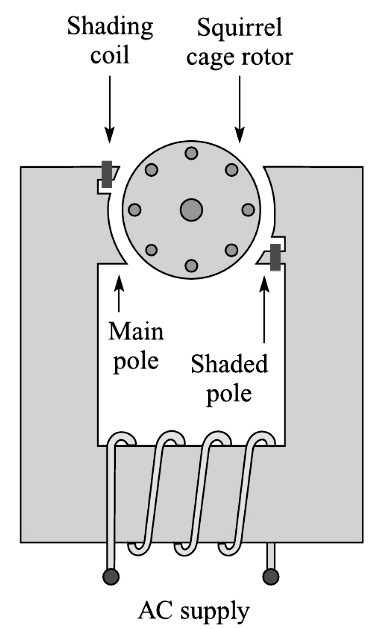

The shaded-pole induction motor is popular because of its simplicity and long life. This motor contains no start windings or centrifugal switch. It contains a squirrel-cage rotor and operates on the principle of a rotating magnetic field created by a shading coil wound on one side of each pole piece. Shaded-pole motors are generally fractional- horsepower motors used for low-torque applications such as operating fans and blowers.

Construction of Shaded Pole Induction Motor

The construction of shaded-pole induction motors is very simple. They have no auxiliary winding, no capacitor, and no centrifugal switch. They are mounted with cheap sleeve bearings and are designed to have air pass over them for cooling.

Stator

The stator has salient poles. Usually, 2 to 4 poles are used. Shaded pole motor is constructed with salient poles in stator. Each pole has its own exciting winding. A 1/3rd portion of each pole core is surrounded by a copper strip forming a closed loop called the shading band or shading coil. Salient pole rotors are large in diameter and shorter in length. They are typically used in lower speed electrical machines (100 RPM to 1500 RPM).

Rotor

The shaded pole motor uses the squirrel cage rotor. For good starting torque and to limit the torque dip during the running condition the rotor bars are provided with a 60-degree skew.

Shading Coil

The shading coil is wound around one end of the pole piece. It is actually a large loop of copper wire or a copper band. The two ends are connected to form a complete circuit. The shading coil acts like a transformer with a shorted secondary winding.

Poles

The shaded pole motor may have two or four poles. The pole is laminated to reduce the core losses. The pole is physically divided into two sections. A heavy, short-circuited copper ring, called the shading coil, is placed on the smaller section of the pole. This section covers around one-third of the pole arc and is called the shaded portion of the pole. The remaining two-third section of the pole arc is referred as unshaded portion. The main single phase winding is wound on the entire pole section. The rotor used is similar to the rotor of any other single phase induction motor.

Shaded Pole Induction Motor Working

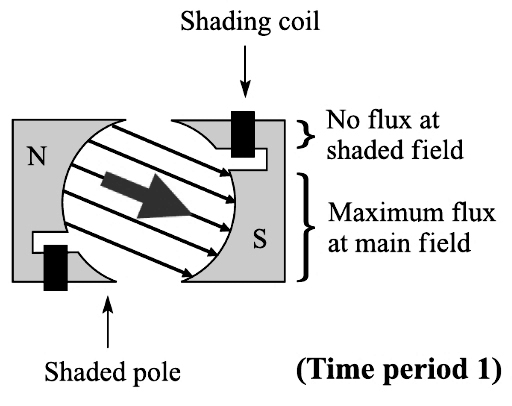

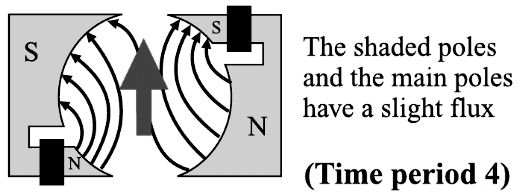

Time Period 1: As the field current increases, a voltage is induced (by transformer action) into the shading ring in such a direction that the resulting current circulating in the ring (in accordance with Lenz’s Law) opposes the main field, weakening the flux in the shaded pole, causing the flux to crowd, or shift, towards the unshaded part of the pole. The magnetic axis of the resulting field, therefore, lies roughly along the center of the unshaded pole.

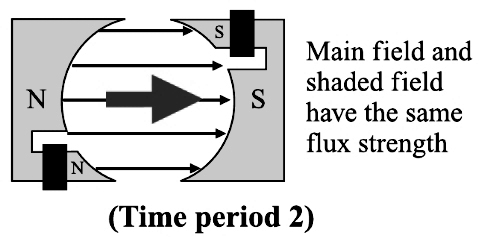

Time Period 2: As the field current approaches its peak value, its rate of change falls towards zero, and no longer induces a voltage into the shading ring so its opposition to the main field disappears. As a result the flux now redistributes itself uniformly across both poles, with the magnetic axis moving clockwise to roughly Centre itself between them.

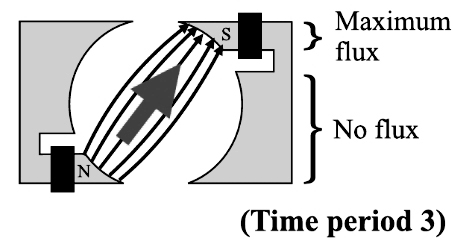

Time Period 3: After passing through its peak value, the field current now decreases rapidly towards zero, causing the main flux to decrease towards zero. At the same time, the voltage induced into the shading ring reverses direction, and now acts to maintain the flux in the shaded pole. As the field current reaches zero, the flux in the main pole disappears, while the flux in the shaded pole reaches its maximum. So the magnetic axis now moves, clockwise, to the center of the shaded pole.

Time Period 4: With the direction of the field current now reversed, the action repeats itself, as described above, but with the polarities of the poles reversed.

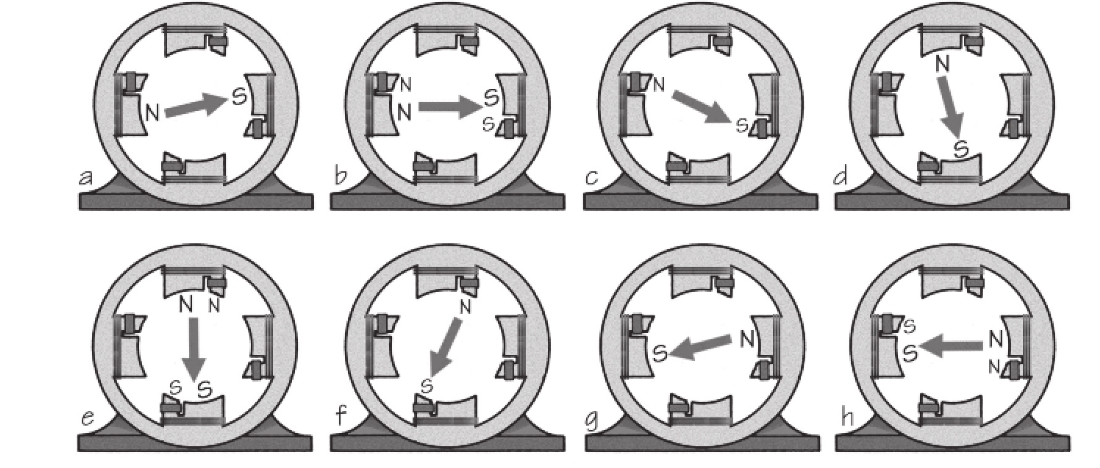

With this action happening at each of the machine’s poles, the result is a rotating magnetic field within the air gap between the stator and rotor. The direction of rotation is always towards the shaded pole.

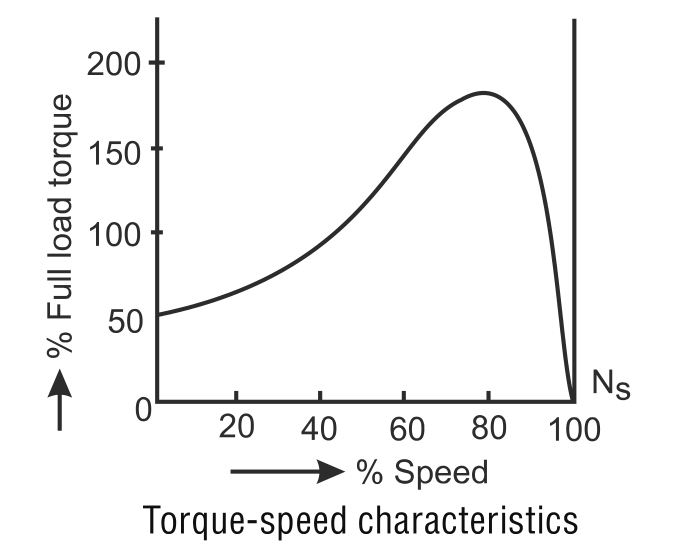

Speed – Torque Characteristics of Shaded Pole motor

A typical speed torque characteristics is shown in Fig. The starting torque of this motor is very small about 50% of full load torque and about 60% of the stall (pull-out) torque. In addition the speed/torque characteristic of the shaded-pole motor exhibits a distinct saddle or dip during run-up owing to the third harmonic component in the MMF waveform. Efficiency is low because of continuous power loss in shading coil.

Losses In shaded Pole Motor

The following losses occur in the shaded-pole motor:

- Stator iron loss

- Main winding copper loss

- Shaded-pole ring copper loss

- I2R loss in the rotor

- Friction loss

Only the main winding copper loss can be determined by direct measurement. Shading ring copper loss is determined by replacing the usual solid copper ring in a few prototype units – with a multiturn insulated winding with the same cross-sectional area. Its current and resistance are then measured. Stator iron losses are measured in a motor with open-circuited shading rings and a cageless rotor. When the friction loss is known, the remaining loss out of the total is principally the rotor copper loss.

Direction of Rotation of Shaded Pole Motor

Its direction of rotation depends upon the position of the shading coil, i.e., which portion of the pole is wrapped with shading coil. The direction of rotation is from unshaded portion of the pole to the shaded portion. Its direction of rotation cannot be reversed unless the position of the poles is reversed.

For enabling reversal of direction of rotation, the construction of the stator must be changed to include:

(1) Two sets of shading coils that are normally open circuited and occupy different positions with respect to the main field winding.

(2) Two main windings that occupy different positions with respect to the shading coils.

(3) A special distributed continuous winding that is placed in a slotted stator core and is tapped at appropriate points with respect to the shading coils.

Applications of Shaded Pole Induction Motor

Shaded-pole motors are inexpensive and reliable, easy to construct, and rugged, but they suffer from a low starting torque, and are relatively inefficient. These types of motors are used for light load applications that require small output horsepower, such as clocks, fans, blowers, pumps, toys, and other items that are inexpensive to make and operate. They are used in Following Application

- To drive the loads which require low starting torque.

- In electronic equipment, etc.

- In exhaust fans

- Hair driers

- In table fans

- Fans for refrigeration & air-conditioning equipment

Disadvantages of Shaded Pole Motor

The main disadvantages of shaded pole motor are

- Low power factor.

- The starting torque is very poor.

- The efficiency is very low as the copper losses are high due to the presence of the copper band.

- The speed reversal is also difficult and expensive as it requires another set of copper rings.