31. Which of the following factors does soil resistance depend?

- Depth of the electrode

- Moisture

- NaCl

Answer.4. All of the above

Explanation:-

The resistance of the earth depends on the following factors.

- Condition of soil.

- The moisture content of the soil.

- The temperature of the soil.

- Depth of electrode at which it is embedded.

- Size, material, and spacing of earth electrode.

- Quality and quantity of coal and salt in the earth pit.

Perfectly dry Earth is very nearly an insulator and it is quite clear that the current flow is due to the moisture contained in the soil; meaning that the earth resistance is electrolytic in character. The specific resistance of any soil, therefore, depends on the extent of moisture and the manner it is held.

Soil resistivity is one of the most important factors affecting the performance of the earthing system because the value of the earth resistance is directly proportional to the resistivity of the medium in which the earth electrodes are installed. At locations where multilayer soil exists at rather shallow depths, the average or apparent resistivity depends on the layer structure, the soil resistivity, and the depth of each layer.

32. The resistance of any grounding system will

- Remain constant

- Always decrease

- Always increase

- Depends on seasonal behavior

Answer.4. Depends on seasonal behavior

Explanation:-

Two samples of soil, when thoroughly dried, may become in fact very good insulators, having a resistivity in excess of 109 Ω-cm. The resistivity of the soil sample is seen to change quite rapidly until approximately 20% or greater moisture content is reached.

The resistivity of the soil is also influenced by temperature. The variation of resistivity of sandy loam, containing 15.2% moisture, with temperature changes from 20°C to -15°C. In this temperature range, the resistivity is seen to vary from 7,200 to 330,000 Ω-cm.

Because soil resistivity directly relates to moisture content and temperature, it is reasonable to assume that the resistance of any grounding system will vary throughout the different seasons of the year.

33. The reactive component is generally taken into account when the ohmic value of the earthing under test is less than

- 2Ω

- 0.5Ω

- 2.5Ω

- 10Ω

Answer.2. 0.5Ω

Explanation:-

If the earth impedance is greater than 1Ω then it is treated that the reactive component of the earthing impedance is negligible and the earth impedance is mainly contributed by the earth resistance. The reactive component is generally taken into account when the ohmic value of the earthing under test is less than 0.5.

34. If the temperature is expected to be quite low, the earth electrodes should be placed around

- 2m below

- 4m below

- 10 m below

- 20 m below

Answer.1. 2m below

Explanation:-

The temperature coefficient of resistivity for soil is negative but is negligible for temperatures above the freezing point. At about 20°C the resistivity change is about 9% per degree Celsius.

Below 0°C, the water in the soil begins to freeze and this causes a tremendous increase in the temperature coefficient so that as the temperature becomes lower the resistivity rises enormously. It is recommended that in areas where the temperature is expected to be quite low, the earth electrodes be about 2 m below the surface.

35. The additional electrode is used in earthing when the resistance to the ground of a single electrode is

- 30Ω

- 50Ω

- 25Ω

- 60Ω

Answer. 25Ω

Explanation:-

Any single rod, pipe, or plate electrode not had a measured resistance to earth of 25Ω or less shall be supplemented by the installation of an additional electrode.

The supplemental electrode is used to help lower the total resistance to the earth by providing additional discharge paths for lightning. When multiple grounding electrodes are installed at a single structure, they shall be spaced not less than 6 ft from each other, and bonded together. Bonding conductors shall not be required to be larger than 6 AWG copper.

The reason for the 6 ft (1.8 m) Separation requirement is so that lightning does not potentially are between the electrodes; it also prevents the radiation patterns into the earth from overlapping so that they can independently dissipate the incoming energy surge.

36. The double earthing is used for

- House earthing

- Single-phase equipment

- 3-phase machines

- Any of the above

Answer.3. 3-phase machines

Explanation:-

Double earth is used for a 3-phase machine and equipment. This gives minimum resistance to the flow of the whole current of that apparatus in case of short circuit, leakage, etc. When double earth is used, there is an advantage of redundancy.

For providing better safety, it is advisable to provide two separate earth wires, from two separate earth electrodes, connected to the same metallic body of the equipment at two different points. This is known as double earthing.

Double earthing is essential, as per Indian Electricity Rule, for metallic bodies of large rating equipment such as transformers, motors, etc. working at 400 V and above or 3-phase machines.

Advantages of double earthing are as follows:

1. Surety of safety, because if at any time, one earthing is ineffective, then another will provide earth path to fault current.

2. As the two earth wires are in parallel, the effective resistance from equipment to earth electrode is reduced.

37. The loop earth wire used shall not be of size less than

- 5 SWG

- 10 SWG

- 7 SWG

- 14 SWG

Answer.4. 14 SWG

Explanation:-

The cross-section of the earth continuity conductor or loop earth wire should not be less than 2.9 mm2 (14 SWG) or half of the size of the subcircuit or half of the installation conductor size.

38. The size of house wiring used as earth wire shall not be of size less than

- 5 SWG

- 14 SWG

- 7 SWG

- 7SWG

Answer.2. 14 SWG

Explanation:-

In the case of household wiring or installation, a 14 SWG hard-drawn bare copper conductor is used as earth wire. For power installations, the size of the earth wire depends upon the rating of the motors installed. The conductor used for earthing purposes should not be of cross-section less than 14 SWG and greater than 64.52 sq. mm from mechanical considerations. From electrical considerations, the copper earth wire should not be of size less than half of the largest current-carrying conductor.

39. In an electric heater, the metal case is connected to

- Phase wire

- Earth wire

- Neutral Wire

- None of these

Answer.2. Earth wire

Explanation:-

Sometimes due to short circuits or due to any other reason large amount of current flows in the circuit. This current produces excessive heat (Q = I2Rt) in the circuit and may cause fire as well. To prevent the damage of electrical appliances against this heating and fire a local earthing is provided just below the electric meter in the house. For this purpose, a thick copper wire is connected to the earth wiring. The other end of this copper wire goes 3 to 4 metros deep inside the earth and is connected to a thick copper plate (50 cm x 50 cm) buried with the mixture of water, salt, and charcoal. To keep the copper plate conducting the ground above the plate is made wet from time to time. In case of excessive current in the live wire, it comes to earth wire and passes through the earth.

In order to work an electrical appliance like electric iron, electric kettle or a room cooler, we need two wires of the supply line, the live wire, and the neutral wire. Sometimes, due to wear and tear or excessive heating, the plastic covering (or insulation) of the connecting wires gets removed or gets burnt and the live wire (which is at a high potential of 220 volts) becomes naked. This naked live wire may touch the metal case (or metal body) of the electrical appliance due to which the case becomes live and comes to the high voltage of 220 volts. If we happen to touch any part of this live appliance, a very high current flows through our body into the earth Due to this high current flowing through our body we get an electric shock.

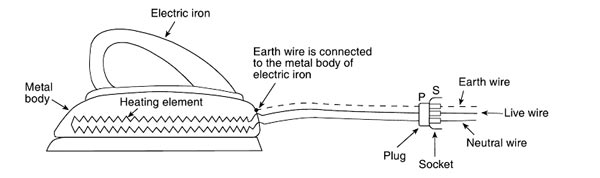

To avoid the risk of electric shocks, the metal body of an electrical appliance is “earthed”. Earthing means to connect the metal case of the electrical appliance to the earth (at zero potential) by means of a metal wire called “earth wire”. in household circuits, we have three wires, the live wire, the neutral wire and the earth wire. One end of the earth wire is buried in the earth. We connect the earth wire to the metal case of the electrical appliance by using a three-pin plug. The metal casing of the appliance will now always remain at the zero potential of the earth. We say that the appliance has been earthed or grounded. Let us make it more clear with the help of a diagram. The figure shows the earthing of an electric iron or press.

The live wire and the neutral wire are connected to the two ends of the heating element whereas the earth wire is connected to the metal body of the electric iron. These three wires are connected to a three-pin plug P. The plug P is connected to a three-pin socket S. Let us see how the earth connection actually works.

If by chance, the live wire touches the metal case of the electric iron (or any other appliance), which has been earthed, then the current passes directly to the earth through the earth wire. It does not need our body to pass the current and, therefore, we do not get an electric shock. Actually, a very heavy current flows through the earth wire and the fuse of household wiring blows out or melts. And it cuts off the power supply. In this way, earthing also saves the electrical appliance from damage due to excessive current.

From the above discussion, we conclude that we earth the metallic body of an electrical appliance to save ourselves from electric shocks. Thus, the earthing of electrical appliances is used as a safety measure. It should be noted that we give earth connections to only those electrical appliances which have the metallic body, which draw heavy current, and which we are liable to touch. For example, electric iron, electric heater, room cooler, and refrigerator, are all provided with earth connections. We, however, do not do earthing of an electric bulb or a tube-light because we hardly touch them when they are on.

Hence in the case of proper earthing no sooner than the live wire touches the metal body than a large amount of current flows in the body of nearly zero resistance and the fuse connected to the appliance blows off to disconnect the circuit. Clearly, the fuse has to be connected to the live wire.

40. __________ earth continuity conductor is simply the wire that connects an electrical system or installation to the earth.

- Earth lead conductor

- Earth continuity conductor

- Earth rod

- Electric rod

Answer.2. Earth continuity conductor

Explanation:-

Earth continuity conductors:- The earth continuity conductor is simply the wire that connects an electrical system or installation to the earth. This earth continuity conductor is connected to an earth electrode in the ground, so it provides a path for the current to travel to the earth.